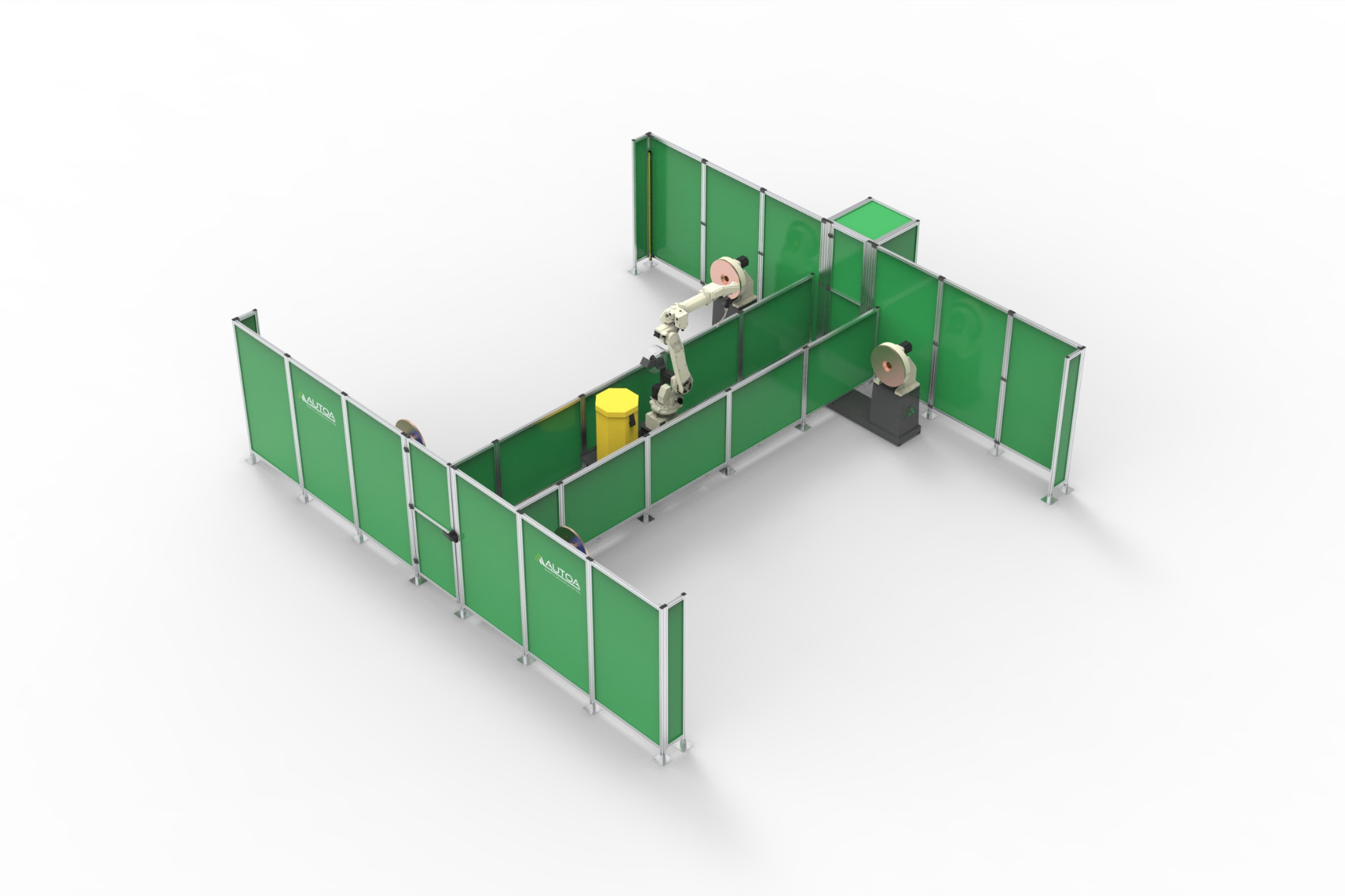

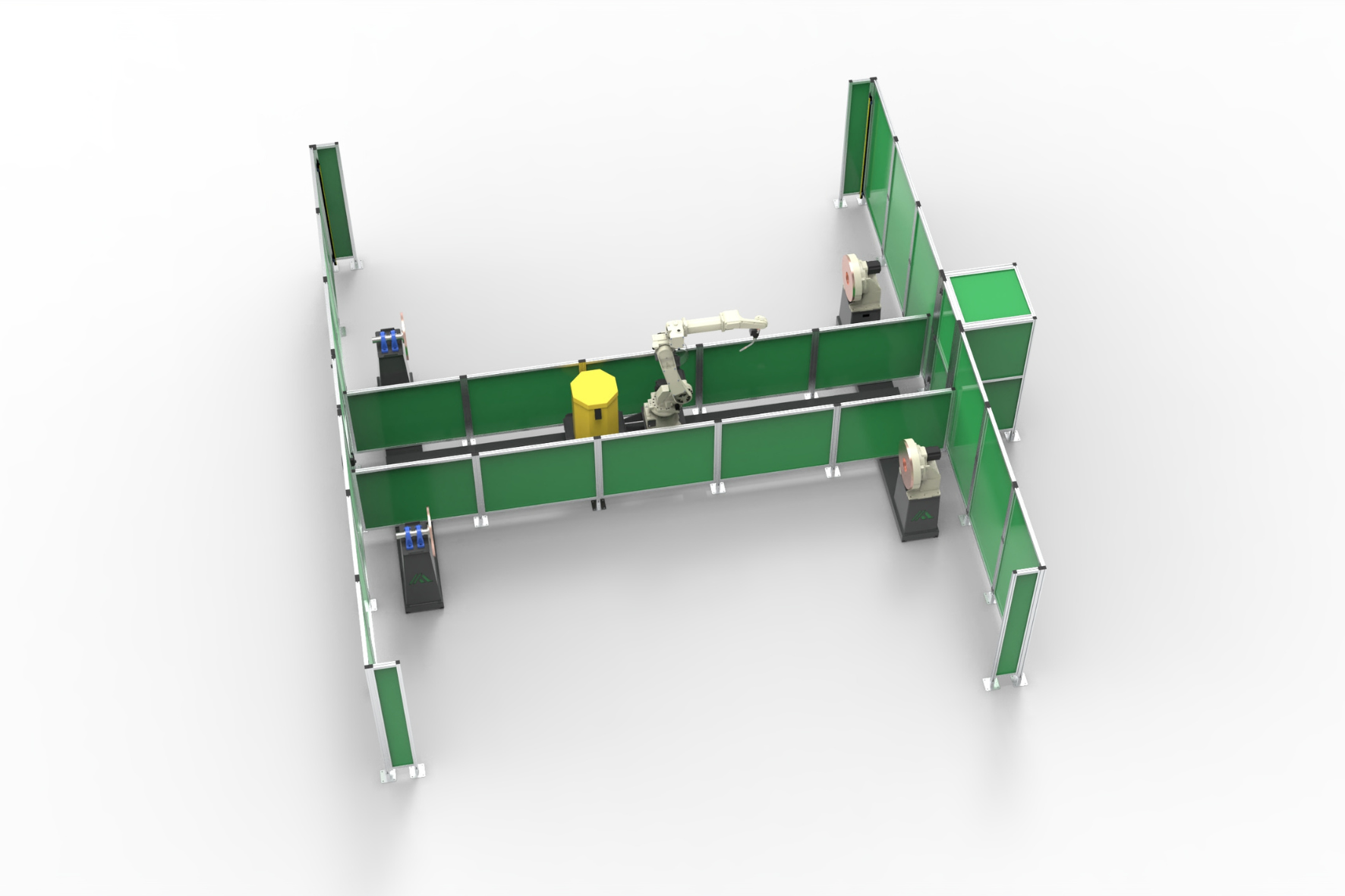

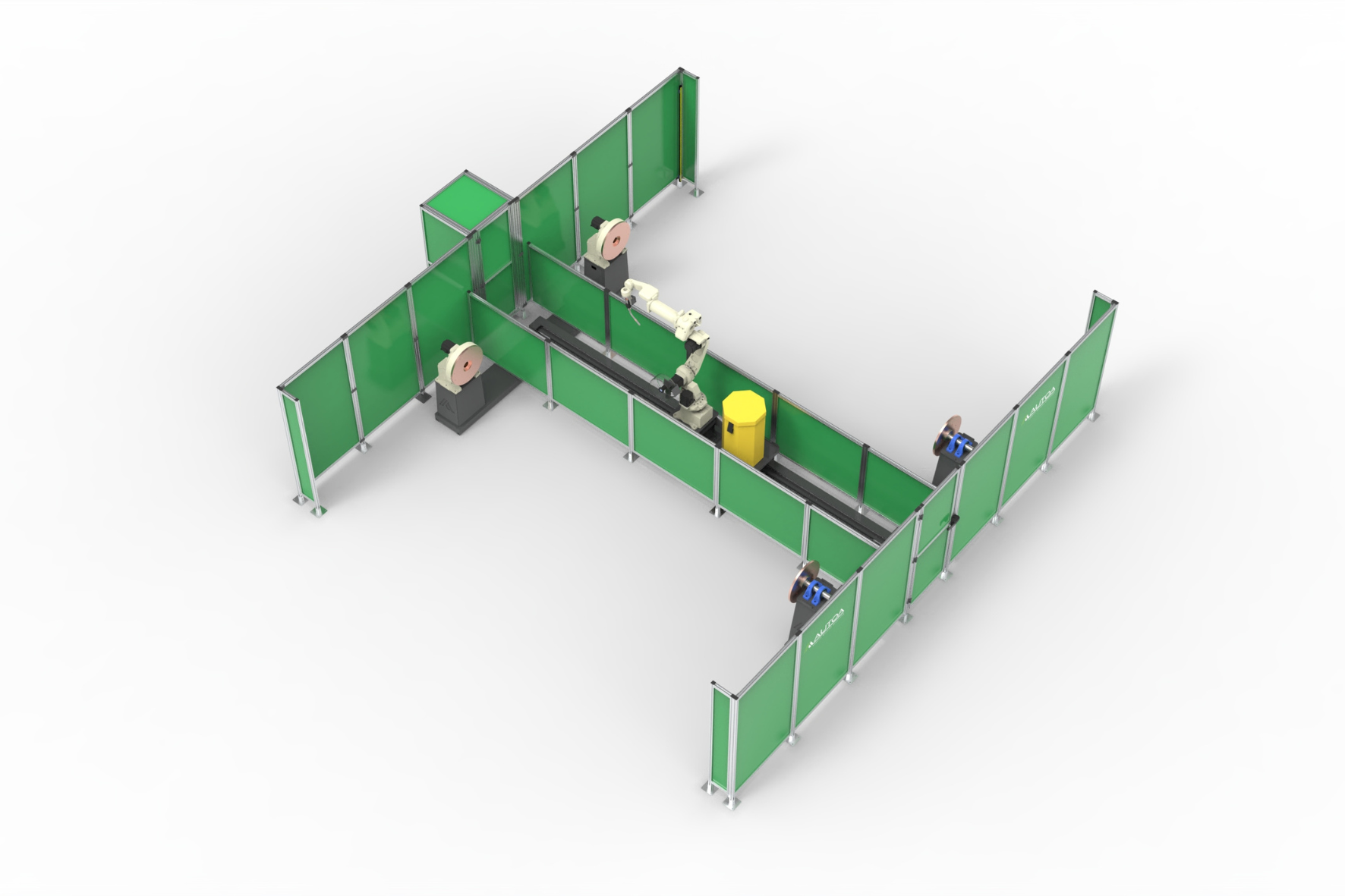

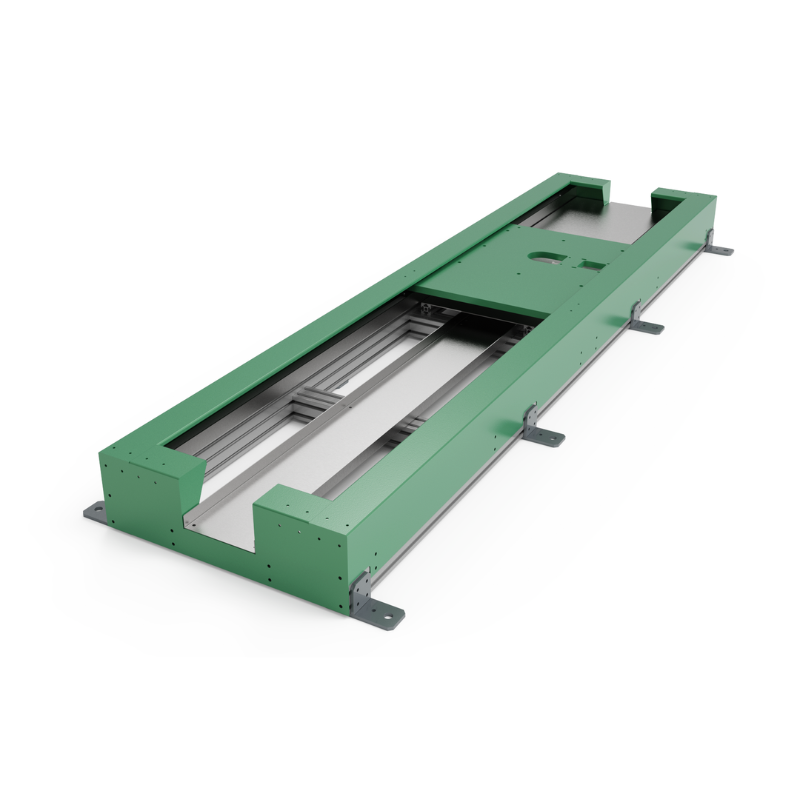

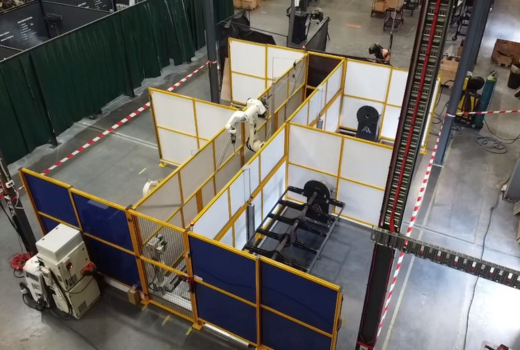

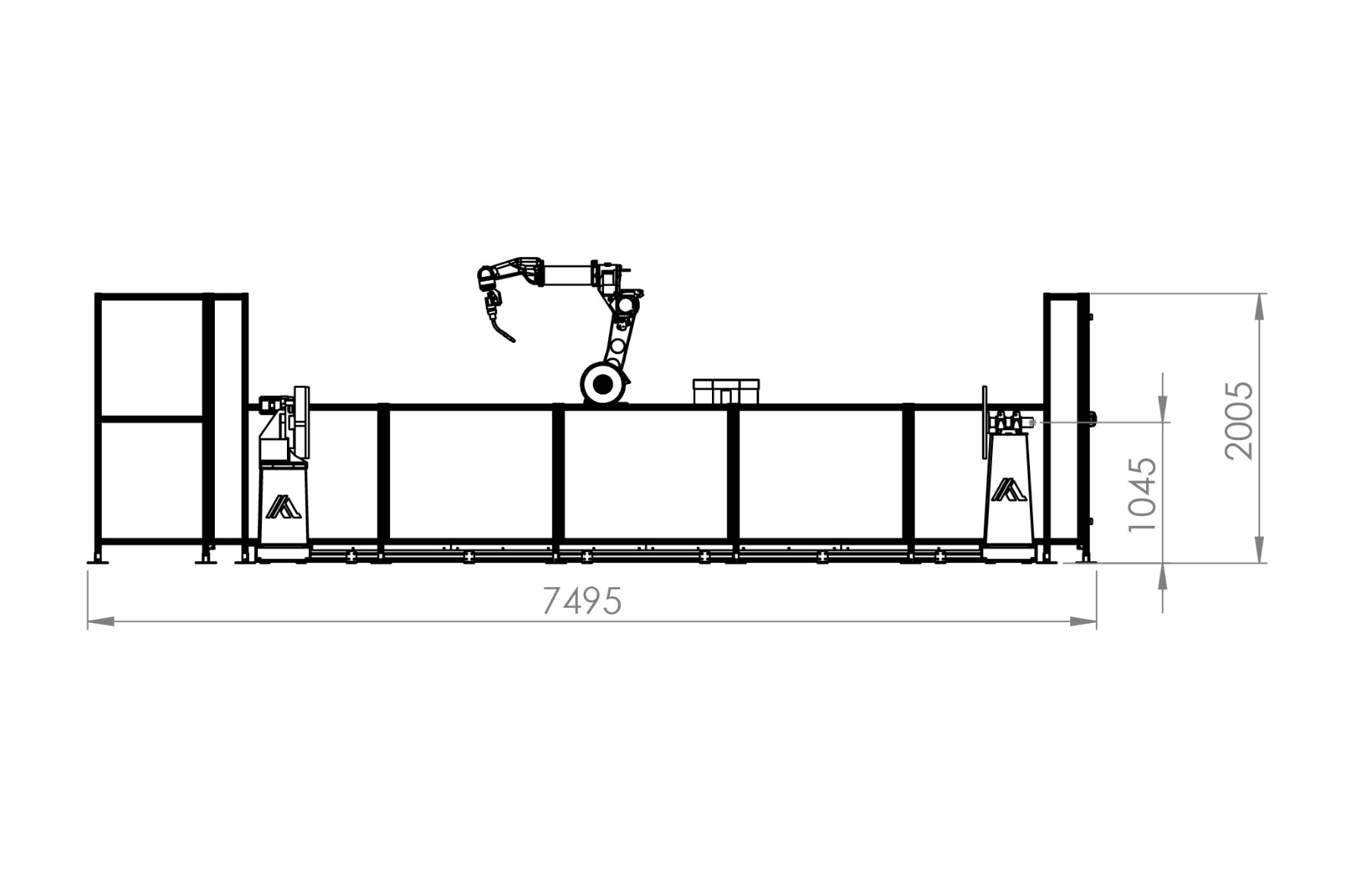

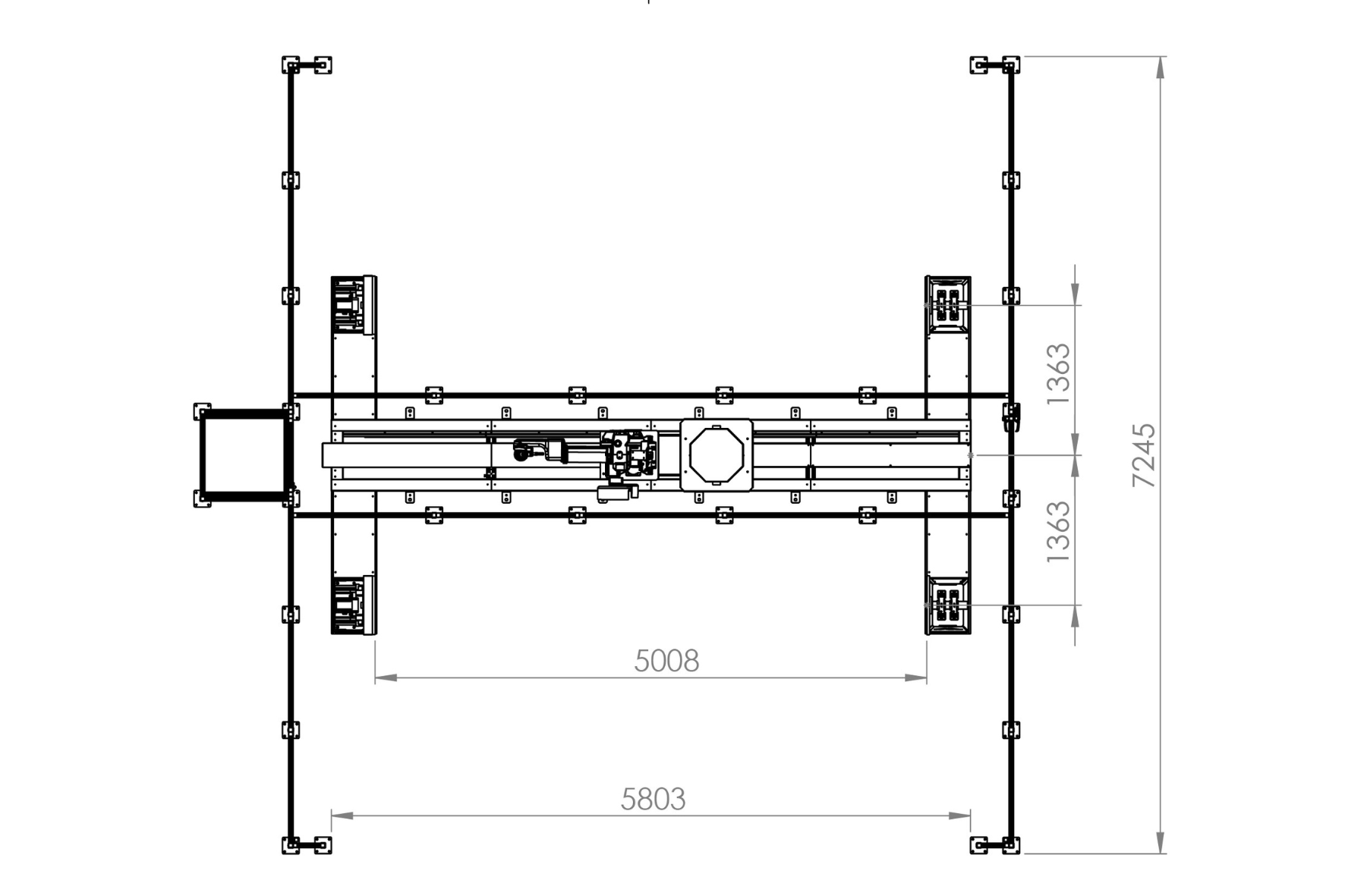

Cell Dimensions.

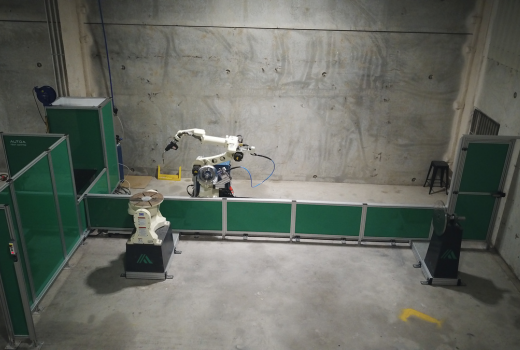

S-4800 RObot WElding Cell

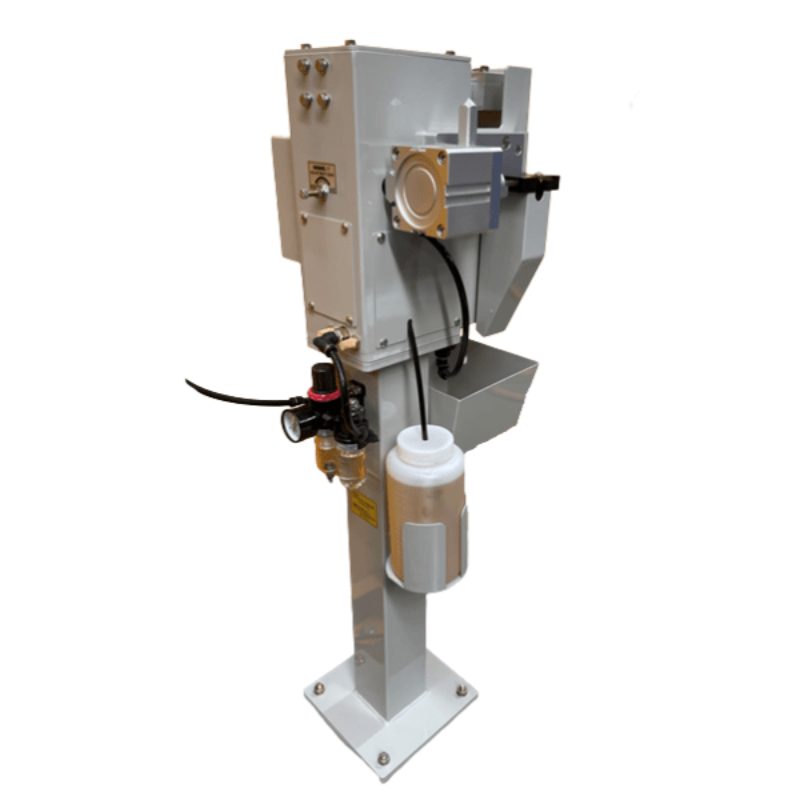

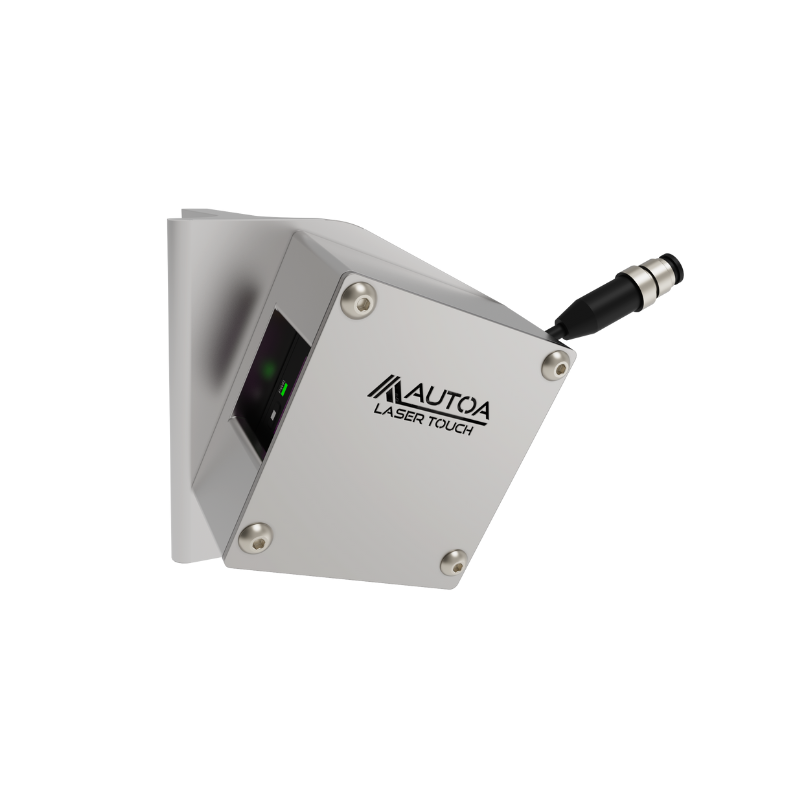

Featured Equipment.

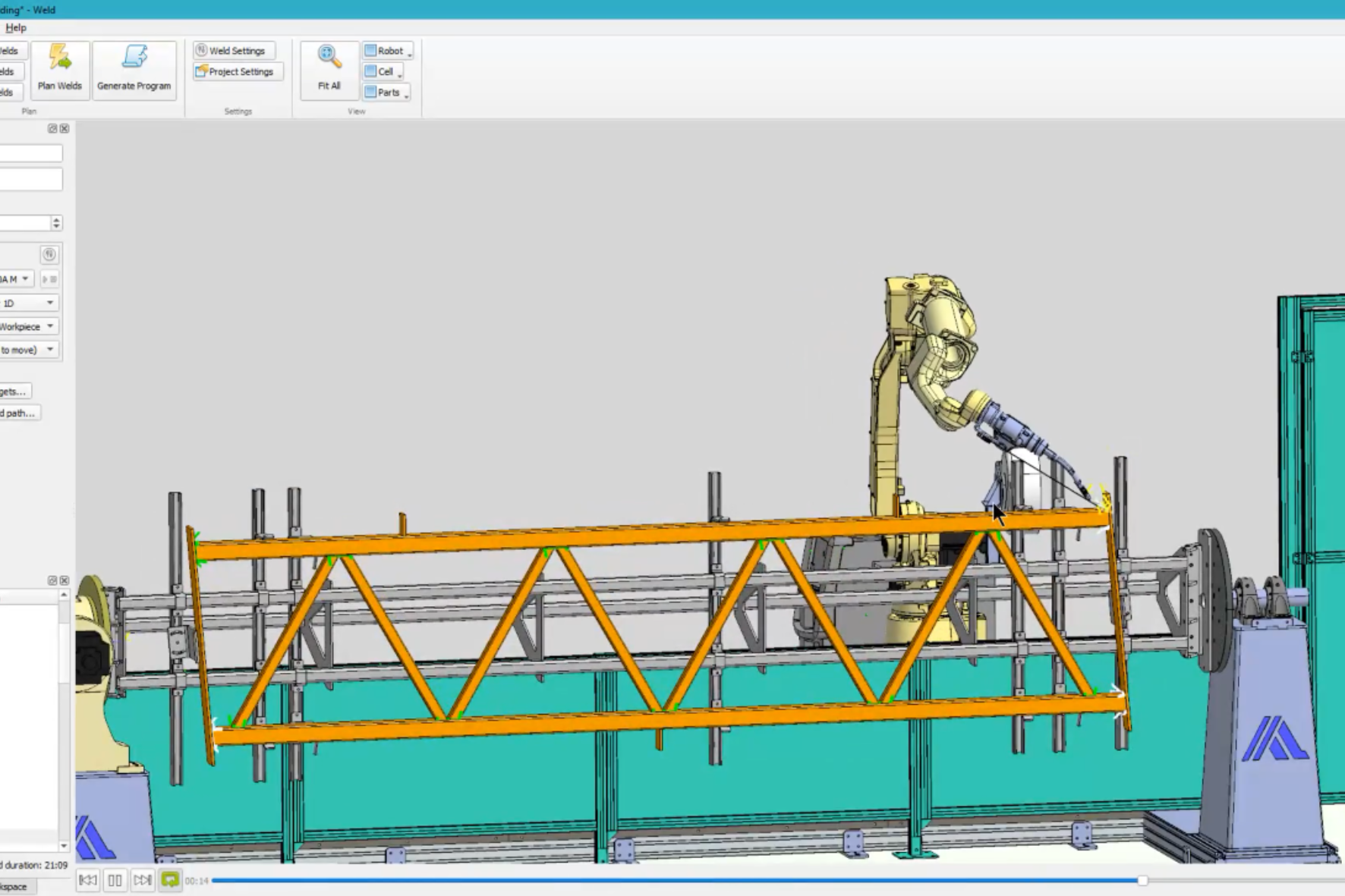

Offline Programming

AutoaWeld Software.

Our revolutionary AI path planning software sets us apart. Powered by advanced algorithms, our software empowers robots to create intelligent, collision-free welding paths, minimising cycle times and enhancing quality. This automation eliminates human errors, ensuring consistent and repeatable results even in challenging scenarios.

CONTACT US

Start Your Robotic Welding Journey Today.

Let’s talk about how our robotic welding solutions can help your business. As a 100% family-owned company, we’re focused on making robotic welding simple and supporting you every step of the way.