Investment in Robotic Welder wins local firm more work

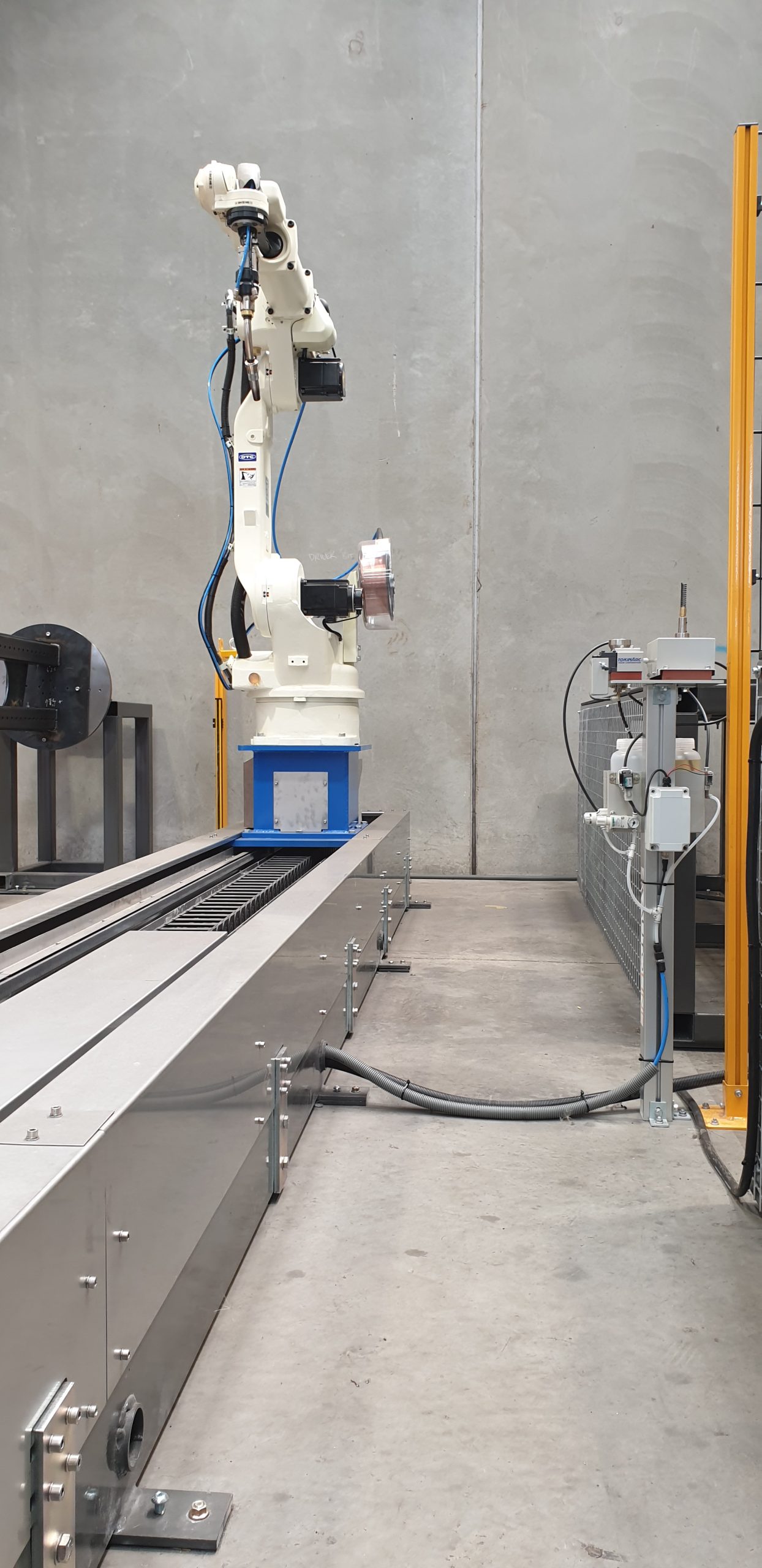

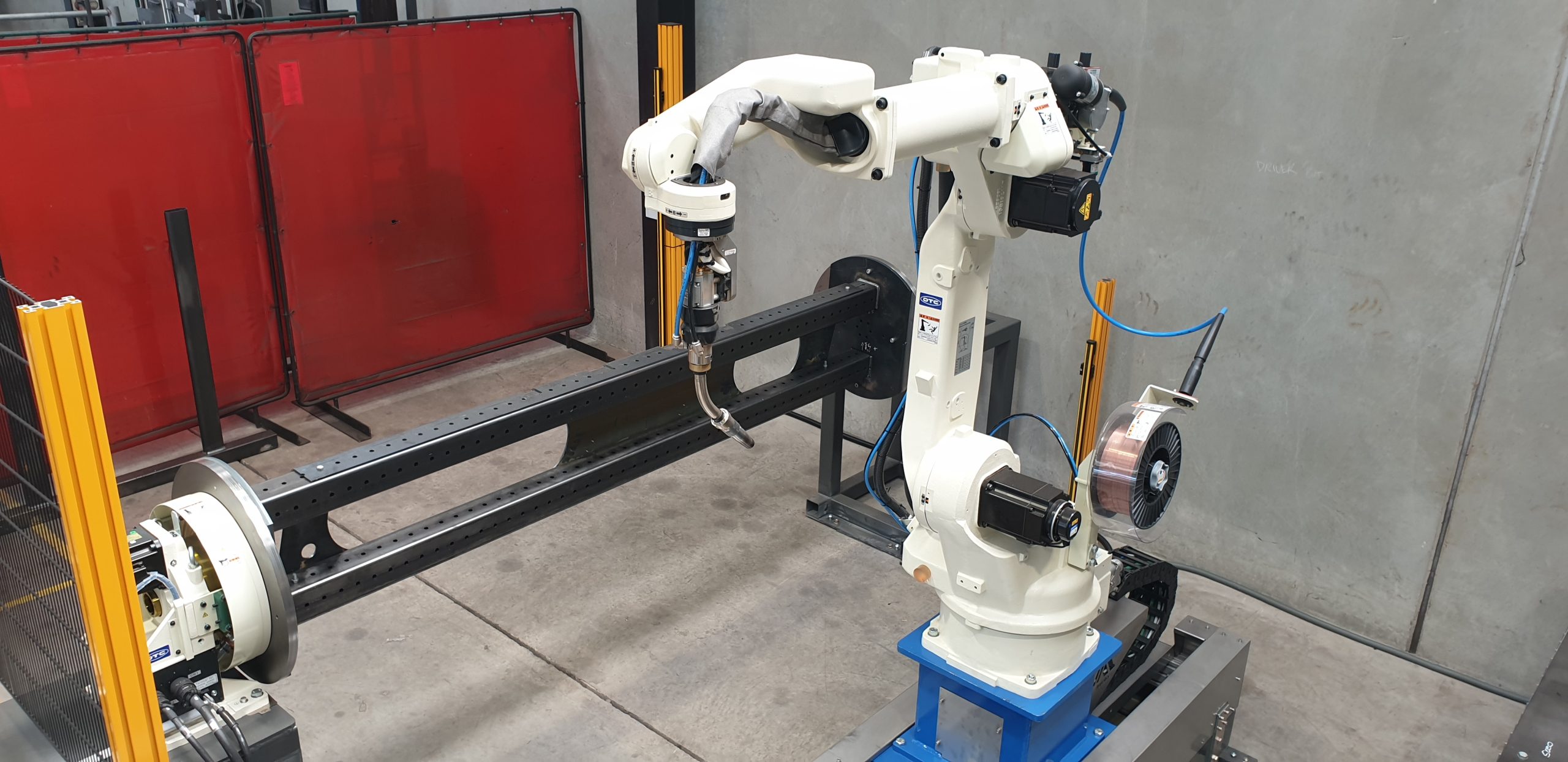

Company: GEA Milfos | Cell: S-4800

EQUIPMENT

- 1x OTC Daihen FD-B6L Through-Arm, Long-Reach Arc Welding Robot with FD11 Robot Controller and Teach Pendant

- 1x OTC Daihen Welbee P500L Welding Power Source + 500A Water Cooled Torch and Water Cooler

- 2x OTC Daihen 1PC500 Positioner Headstock

- 1x Autoa Servo Controller Robot Slider, 5000mm Travel

- 1x Autoa Tip Cleaning Station

- Safety Componentry Integrated

TESTIMONIAL

With an investment payback period of a couple of years, incorporating a robotic welder into the manufacturing line was a “no-brainer” for the Hamilton branch of a global farm engineering firm.

GEA is one of the world’s largest suppliers of food processing technology and related industries. The global group specialises in providing sustainable solutions for the farming industry to improve profitability, flexibility and animal welfare while reducing emissions. Rakesh Singh, the director of production farm technologies of the Hamilton branch of GEA, says they started looking into robotic welders as part of a push to get more work from their sister company overseas.

“We needed to show we were more productive with a robotic welder than doing it manually, and to demonstrate we could handle a higher capacity of work,” Rakesh says. “The project we did to get sign off on the $330,000 robotic welder, showed actual savings of $37,000 in the first year – and that was on just one of the core parts we manufacture.”

The part, called a bail/bale (the partition between cow stalls in a milking shed), is just one of many high-volume components the company produces for farming clients around the world. It takes 45 minutes to weld a bail/bale manually and only 7-8 minutes for the robotic welder to finish the job, he says. “When you’re making between 12-1300 of them annually, the savings add up substantially.”

“After that pilot project proved successful, we started using the robot for other high volume parts too and we saved thousands each year, the robot literally paid for itself.” Order intake has increased since incorporating the robotic welder in 2020 and they’d recommend anyone else in the industry to upgrade to a robotic welder too, Rakesh says.

“If you’re doing high numbers of anything it’s definitely a no brainer. We haven’t had to lay off staff as a result, we’re busy enough that we can utilise their labour in other areas of production.”

Contact Us

Start Your Robotic Welding Journey Today!

Let’s talk about how our robotic welding solutions can help your business. As a 100% family-owned company, we’re focused on making robotic welding simple and supporting you every step of the way.