Background

Te Pari is a third-generation, family-owned business based in Oamaru, New Zealand. Renowned for their innovation in livestock handling systems, Te Pari designs and manufactures premium cattle and sheep equipment for farmers across the globe. With a strong focus on productivity, quality, and animal welfare, Te Pari continues to lead the way in agricultural engineering.

To help meet growing demand and maintain consistent quality, Te Pari worked closely with Autoa to integrate robotic welding at Te Pari into their production process.

Project Overview

Customer: Te Pari

Product: Livestock Equipment & Handling Solutions

Country: Southland, New Zealand

Installed: 2021

Industry: Agricultural Equipment Manufacturing

Solution: S-6000 Robot Welding Cell

Featured Equipment: Yaskawa AR3120 Robot, OTC Daihen P500L Power Source + 350A Air Cooled Torch, Yaskawa HM-1000D Positioner Headstocks, Yaskawa TM-1000D Positioner Tailstocks, Yaskawa TSL-1000 Robot Slider, Tip Cleaning Station, Integrated Safety Componentry.

The Solution

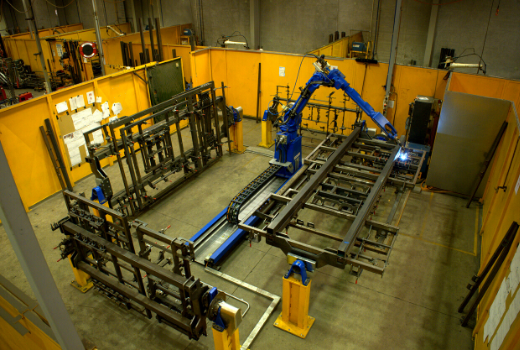

Autoa worked closely with Te Pari to integrate the S-6000 robotic welding cell into their manufacturing workflow. The system was designed to accommodate large, complex livestock handling components, delivering consistent and precise welds at scale.

The cell features a long-reach Yaskawa robot on a 4m linear track, combined with coordinated multi-axis positioners for part rotation and access. The integration of high-performance welding equipment ensures quality control while minimising rework and waste.

Te Pari’s in-house engineering team handled much of the jig design and set-up, with Autoa providing specialised training and ongoing technical support to ensure long-term performance and flexibility.

Robotic welding cell with servo-driven track

Precision MIG welding with custom jig fixtures

Inside the S-6000 robotic welding cell

“Our business has expanded exponentially with the use of robotics,” Blampied says. “Robots make the process more efficient, which means you get busier and integrate more robots and then need to employ more people to keep up with the increased workload downstream in assembly and dispatch.”

The Results

Since the installation of the S-6000 cell, robotic welding at Te Pari has contributed to gains in both productivity and consistency on the factory floor. The system has reduced the time required for manual welding, allowing jobs to move through production more efficiently. This has supported Te Pari’s ability to keep up with demand without compromising on quality.

Weld quality has been consistently reliable. The robotic cell produces clean, repeatable welds that meet the standards required for livestock handling equipment — where strength and precision matter. With accurate jigging and stable weld paths, the amount of rework required has decreased. That’s helped reduce downtime and improve material use across the line.

The shift to robotic welding has also taken some of the pressure off the welding team. Staff have been able to focus more on assembly and dispatch, where output has increased alongside production.

The IMPACT ON Te pari’s business

Robotic welding has become an important part of Te Pari’s manufacturing capability. The S-6000 cell has supported their ability to grow production while maintaining the product quality their customers expect.

Nick Blampied describes robotic welding as a key part of Te Pari’s expansion. As output increased, it created opportunities to invest in further improvements across the business — including hiring more staff in assembly and dispatch to handle the increased volume downstream.

Rather than replacing jobs, robotic welding has enabled the team to work more efficiently and focus on areas where human input adds the most value. With consistent weld quality, reduced downtime, and a more reliable production process, robotic welding at Te Pari continues to support an approach that’s well-positioned for growth in New Zealand and internationally.

The partnership with Autoa Robot Welding has also given Te Pari access to support, training, and welding expertise as needed, ensuring the system continues to deliver value well beyond the initial installation.

Bird’s-eye view of Te Pari’s S-6000 robotic welding cell

Yaskawa AR3120 robot on a 4m linear track

Yaskawa AR3120 robot welding livestock handling components

Contact Us

Start Your Robotic Welding Journey Today!

Let’s talk about how our robotic welding solutions can help your business. As a 100% family-owned company, we’re focused on making robotic welding simple and supporting you every step of the way.