Robotic Welding Programming Software That Simplifies Setup.

Published on 29 April 2025

AutoaWeld: Robotic Welding Programming Software That Simplifies Setup

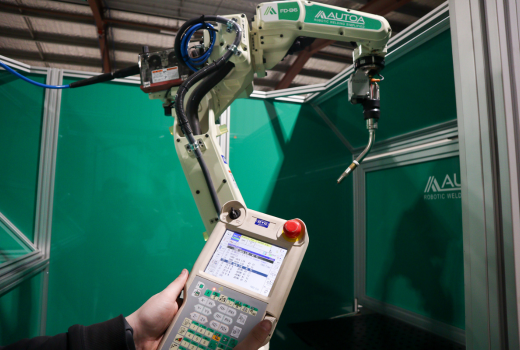

AutoaWeld is robotic welding programming software built to take the complexity out of robot setup. Using AI-powered path planning and an intuitive interface, AutoaWeld makes it faster and easier to program weld paths—without the need for manual coding or specialist skills.

With AutoaWeld, you can:

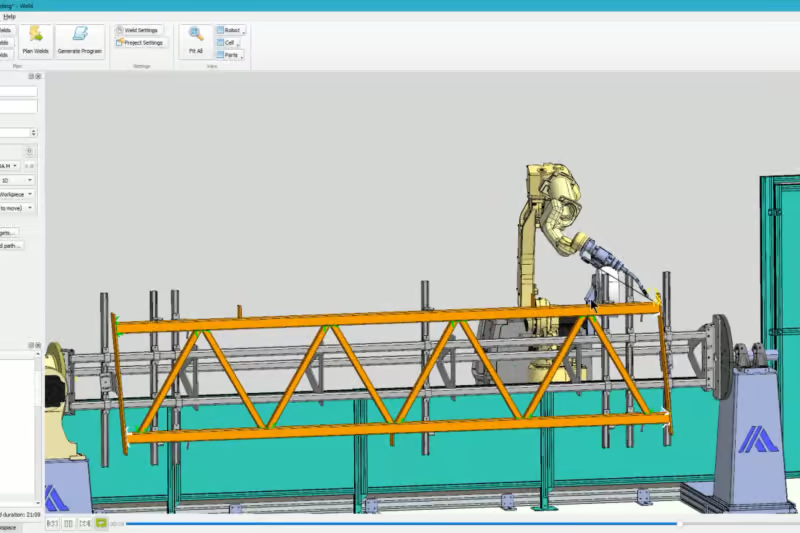

- Import a CAD file and automatically identify weld seams

- Optimise torch angles, motion paths, and sequences

- Simulate the weld process to check for accuracy and cycle time

- Export a ready-to-run program direct to your robot

If programming has been a barrier to adding robotic welding, AutoaWeld makes it simple to get started—and easy to keep running.

The Problem with Traditional Robot Programming

Many manufacturers recognise the benefits of robotic welding—greater output, greater consistency, and improved quality.

But traditional programming can add extra steps that slow down production:

- Manual setup is time-consuming – Each weld path needs to be programmed individually.

- Specialised programming skills are needed – Not every business has a robot programmer on staff.

- High-mix, low-volume production can be inefficient – Reprogramming for small runs often adds extra effort.

AutoaWeld was developed specifically to overcome these challenges—streamlining programming so businesses can get more value from their robots.

It makes programming faster, easier, and flexible enough to handle changing production needs without slowing down operations.

How It Works

AutoaWeld takes the complexity out of robot programming—turning CAD files into ready-to-run weld paths quickly and accurately. Using built-in AI and an intuitive interface, AutoaWeld identifies weld locations, plans paths, and generates robot-ready programs with minimal input. The result is a faster, more streamlined setup process that gets your robotic welding cell working sooner—with less effort, fewer delays, and no need for specialist coding skills.

Why AutoaWeld Changes the Game

Faster Setup, More Welding

AutoaWeld cuts programming time from hours—or even days—down to minutes. By automating weld identification and path planning, it reduces setup effort and gets your robotic welding cell into production faster.

Flexible for High-Mix, Low-Volume Work

With AutoaWeld, reprogramming for different parts or small production runs is fast and efficient. The software makes it easy to adjust for new jobs without needing to manually reteach the robot.

Reliable Weld Paths, Every Time

AutoaWeld’s AI-driven path planning ensures consistent torch angles, efficient travel paths, and 100% collision avoidance—reducing manual error and improving weld quality.

Maximises Robot Productivity

Every minute your robot is welding, you’re adding value. AutoaWeld helps maximise uptime by simplifying programming, cutting downtime, and keeping your production running smoothly.

AutoaWeld Software: Making Robotic Welding Accessible for Every Manufacturer

AutoaWeld is designed to make robotic welding practical and accessible—whether you’re running high-volume production or smaller custom jobs. By removing the complexity from robot programming, AutoaWeld gives more businesses the ability to improve weld quality, increase throughput, and reduce manual setup time without needing specialist programming skills. With faster setup, built-in AI planning, and an intuitive workflow, AutoaWeld simplifies robotic welding—helping manufacturers of all sizes get more value from their welding operations.

If programming has been a barrier to adding robotic welding, AutoaWeld provides a straightforward way to move forward with confidence.

Ready to program less and weld more with AutoaWeld?

hello@autoaweld.com | AU: 1800 573 228 | NZ: 0800 37 55 66

Share this article