Background

Resero is a leading manufacturer of high-quality furniture, specialising in innovative solutions for education, healthcare, and public spaces. With operations in New Zealand and Australia, they are known for their commitment to durability, functionality, and design excellence. To maintain their competitive edge, Resero sought to enhance their welding capabilities.

Project Overview

Customer: Resero

Product: Furniture for Education, Healthcare, and Public Spaces

Country: Hastings, New Zealand

Installed: 2022

Industry: Furniture Manufacturer

Solution: Custom Robotic Welding Cell

Featured Equipment: OTC Daihen FD-V8 Welding Robot, FD11 Controller and Teach Pendant, OTC Daihen Welbee M400 Welder, Welding Positioner Rotator, Integrated Safety Componentry.

The Solution

Autoa worked closely with Resero Group to implement a custom robotic welding cell designed to streamline their manufacturing process, ensuring consistency and efficiency. The system was fully operational within a short timeframe, ensuring a smooth transition to automated welding with minimal disruption.

Engineered for efficiency, the robotic welding cell enhances production flow by delivering precise, repeatable welds while reducing manual handling. Custom fixtures ensure accurate part positioning, allowing for greater consistency across different product variations. To support long-term success, Resero’s team received comprehensive operator training to maximise the benefits of robotic welding.

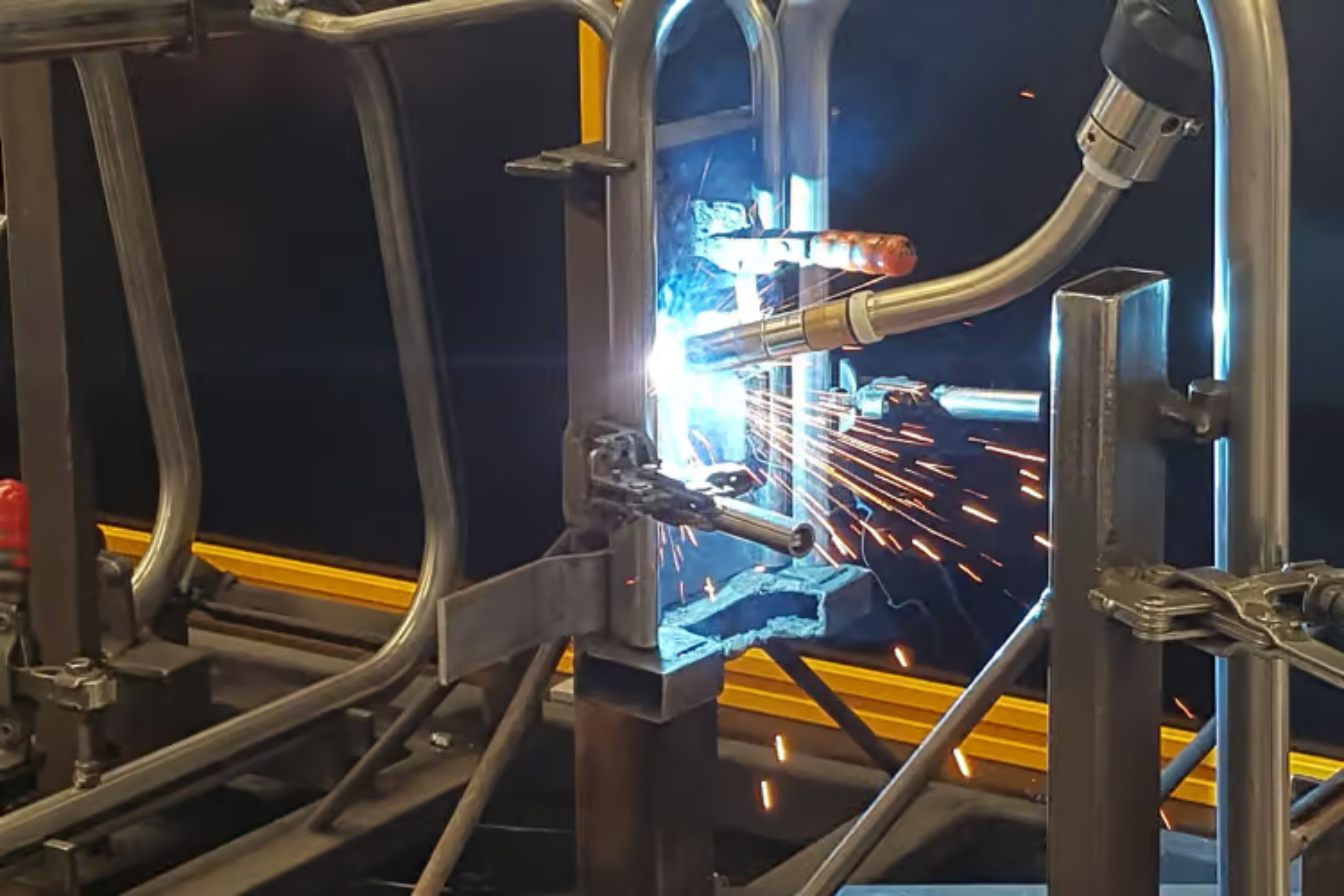

Installed robotic welding cells

Robotic welding delivering consistent, high-quality welds on chair frames

Robot welded furniture frames

The Results

The robotic welding solution has improved Resero Group’s production efficiency while maintaining their high quality standards. By streamlining the welding process, Resero has optimised workflow and freed up skilled operators for other critical tasks. With automated welding handling repetitive work, the team can focus on high-value manufacturing areas, enhancing productivity and supporting future growth. This shift has also improved workplace safety and efficiency.

The Impact on Resero’s Business

Integrating robotic welding has strengthened consistency and reliability in Resero’s manufacturing process. This investment has also created long-term benefits beyond immediate productivity gains. With skilled operators focusing on more complex, value-driven tasks, Resero has built a more flexible and future-ready production environment.

Increased efficiency and cost savings have reinforced their competitive edge, ensuring they can meet demand while delivering high-quality furniture for education, healthcare, and public spaces.

Custom robotic welding cell installed and ready for production

Configured welding cell with fixturing for furniture production

Contact Us

Start Your Robotic Welding Journey Today!

Let’s talk about how our robotic welding solutions can help your business. As a 100% family-owned company, we’re focused on making robotic welding simple and supporting you every step of the way.