Background

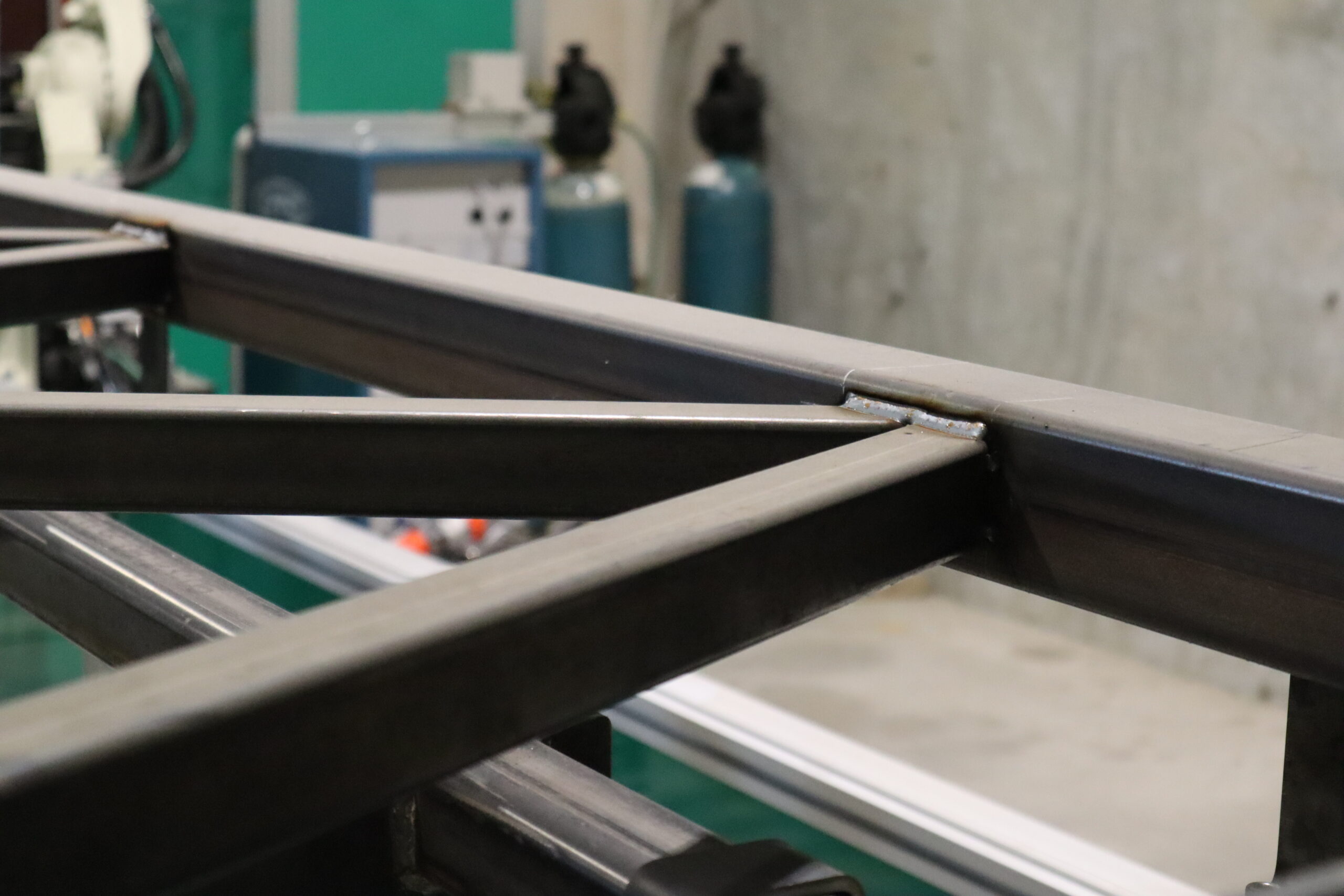

The Autoa Training Centre was built to support hands-on learning and skill development in robotic welding. It gives our team and our customers a space to train on real equipment, run live welds, and gain experience with the tools and software behind every Autoa system. Whether it’s onboarding operators or trialling new processes, the Autoa Training Centre plays a key role in building confidence and capability with robotic welding.

Project Overview

Customer: Autoa

Product: Robotic Welding Cell for Training Centre

Country: Blenheim, New Zealand

Installed: 2022

Industry: Robotic Welding

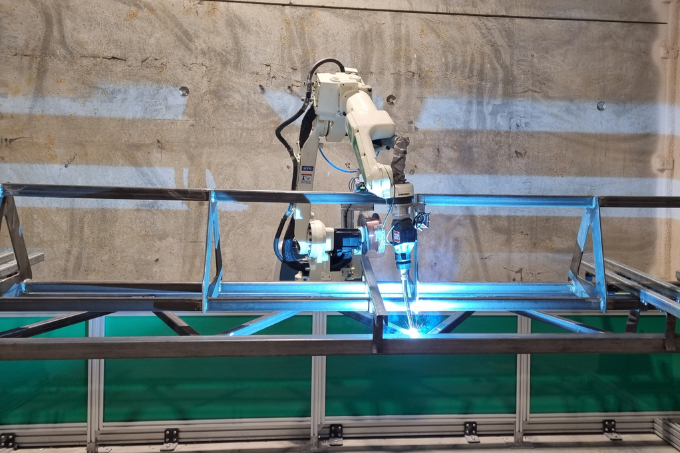

Solution: S-4800 Robot Welding Cell

Featured Equipment: OTC Daihen FD-B6 Through Arm Welding Robot, OTC Daihen FD19 Controller + Teach Pendant, OTC Daihen Welbee P502L Welding Power Source + 350A Air Cooled Torch, Heavy Duty Manual 2-Position Rotator Cell, Tip Cleaning Station, Integrated Safety Componentry.

Come See it for yourself

Front view of the S-4800 robotic welding cell

Contact Us

Stay Connected To Your Robot Welding Cell.

Talk to us about connecting your robot welding cell with Autoa remote monitoring software. Gain live visibility, direct technical support, and fewer production interruptions with software that keeps your welding operations performing at their best.