WELDING THE BIG JOBS, Autoa is the Answer

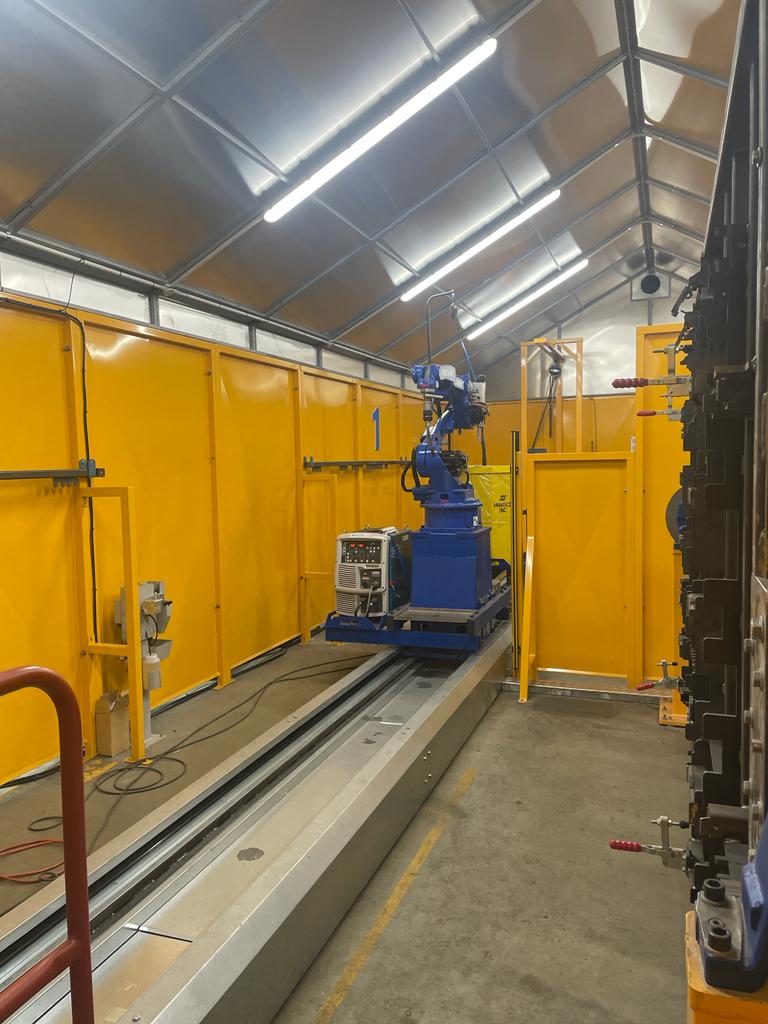

Company: Te Pari | Cell: S-6000

EQUIPMENT

- 1x Yaskawa AR3120 Through-Arm, Long-Reach Arc Welding Robot with YRC1000 Controller and Teach Pendant

- 1x OTC Daihen Welbee P500L Welding Power Source + 350A Air Cooled Torch

- 2x Yaskawa HM-1000D Positioner Headstock

- 2x Yaskawa TM-1000D Positioner Tailstock

- 1x Yaskawa TSL-1000 Robot Slider, 4000mm Travel

- 1x Autoa Tip Cleaning Station

- Safety Componentry Integrated

TESTIMONIAL

Using robotics in engineering manufacturing improves productivity and quality and drives business growth, says Nick Blampied of the revolutionary livestock management business, Te Pari. Te Pari is a third-generation Kiwi business that designs and manufactures cattle and sheep handling and hardware solutions.

Blampied says the Oamaru-based business invested in their first welding robot in 2007 and were so impressed with the results, continued to expand, and integrate more Autoa robots into its production line.

“Our business has expanded exponentially with the use of robotics,” Blampied says. “Robots make the process more efficient, which means you get busier and integrate more robots and then need to employ more people to keep up with the increased workload downstream in assembly and dispatch.”

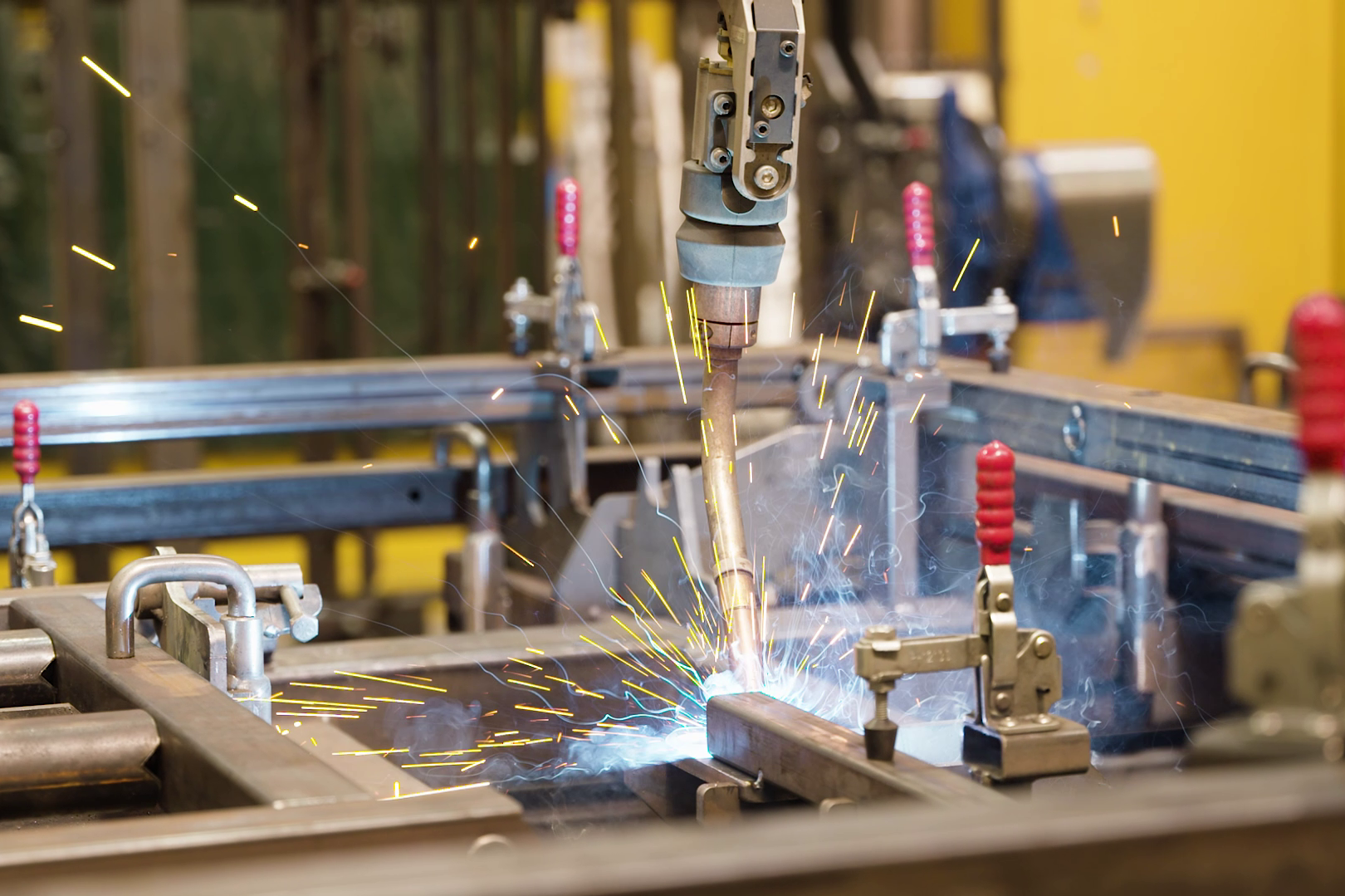

Welding robots provide a consistently high-quality finish and eliminate problems associated with welder fatigue, substantially improve worker health and safety, and reduce defect rates and waste. After the initial investment into robots and the associated jigging and programming, Autoa’s robot welders consistently and efficiently produce top quality results, he says.

“The secret to a robot welder working well is having very accurate cut parts and jigs, once you complete that initial set up, you get very high output.” Most of the set-up has been done in-house by their own engineers, and Autoa provides the training for specific functions as required.

“Autoa has been great to deal with over the years. They provide excellent service and can supply a wide range of parts and welding consumables in a timely manner.”

Contact Us

Start Your Robotic Welding Journey Today!

Let’s talk about how our robotic welding solutions can help your business. As a 100% family-owned company, we’re focused on making robotic welding simple and supporting you every step of the way.