Standard Robotic Welding Cells

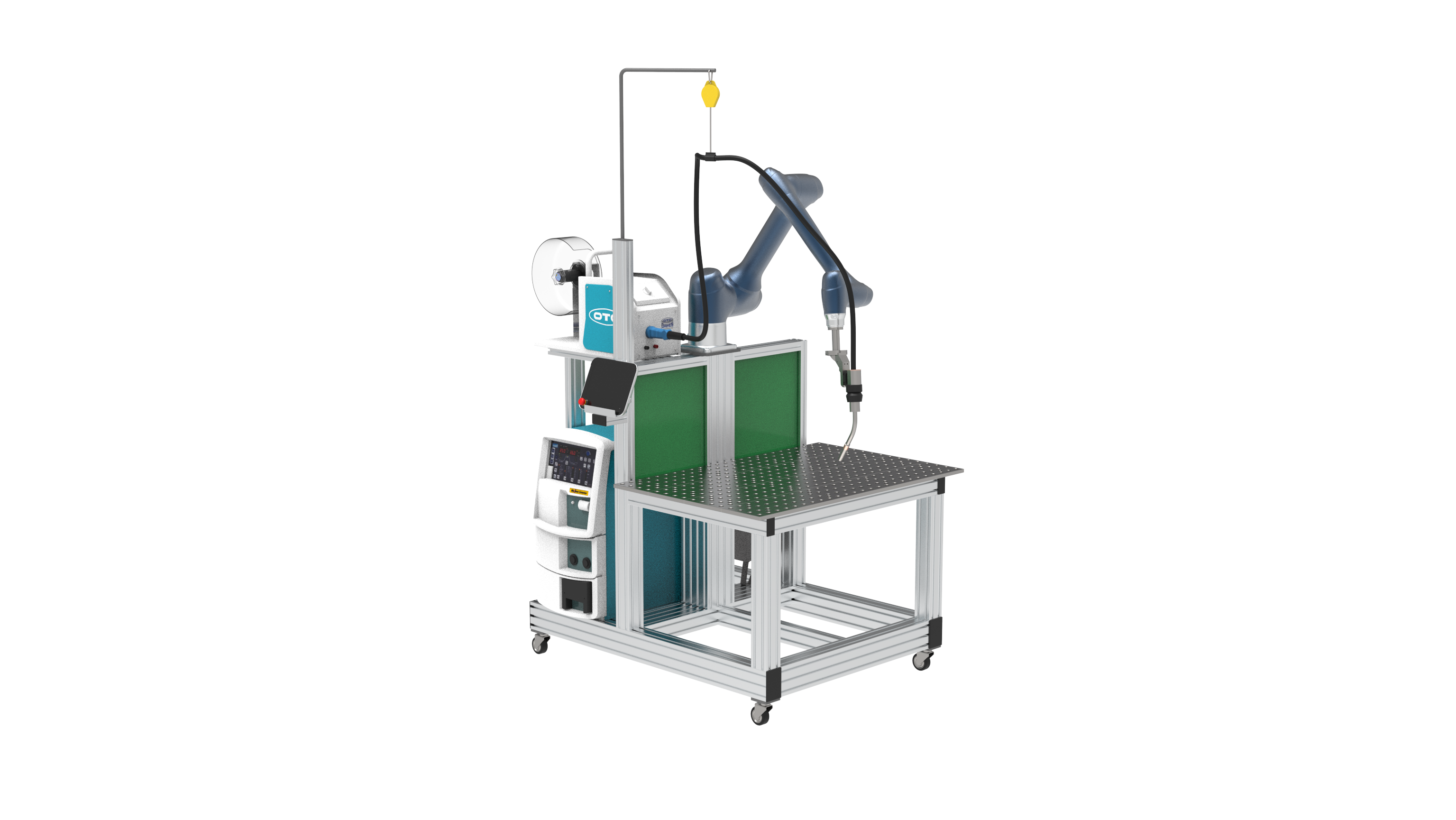

Autoa Compact Series.

The Autoa Compact Series robotic welding cells are tailored for small to mid-sized businesses, addressing challenges like space constraints, investment costs, and skilled labour shortages. Designed to maximise productivity within a minimal footprint, the Compact Series offers a quick return on investment for companies with limited floor space.

Ideal for upgrading from manual to robotic welding, the Compact Series enhances efficiency, quality, and ease of use, making the shift to automated welding seamless and straightforward.

Standard Robotic Welding Cells

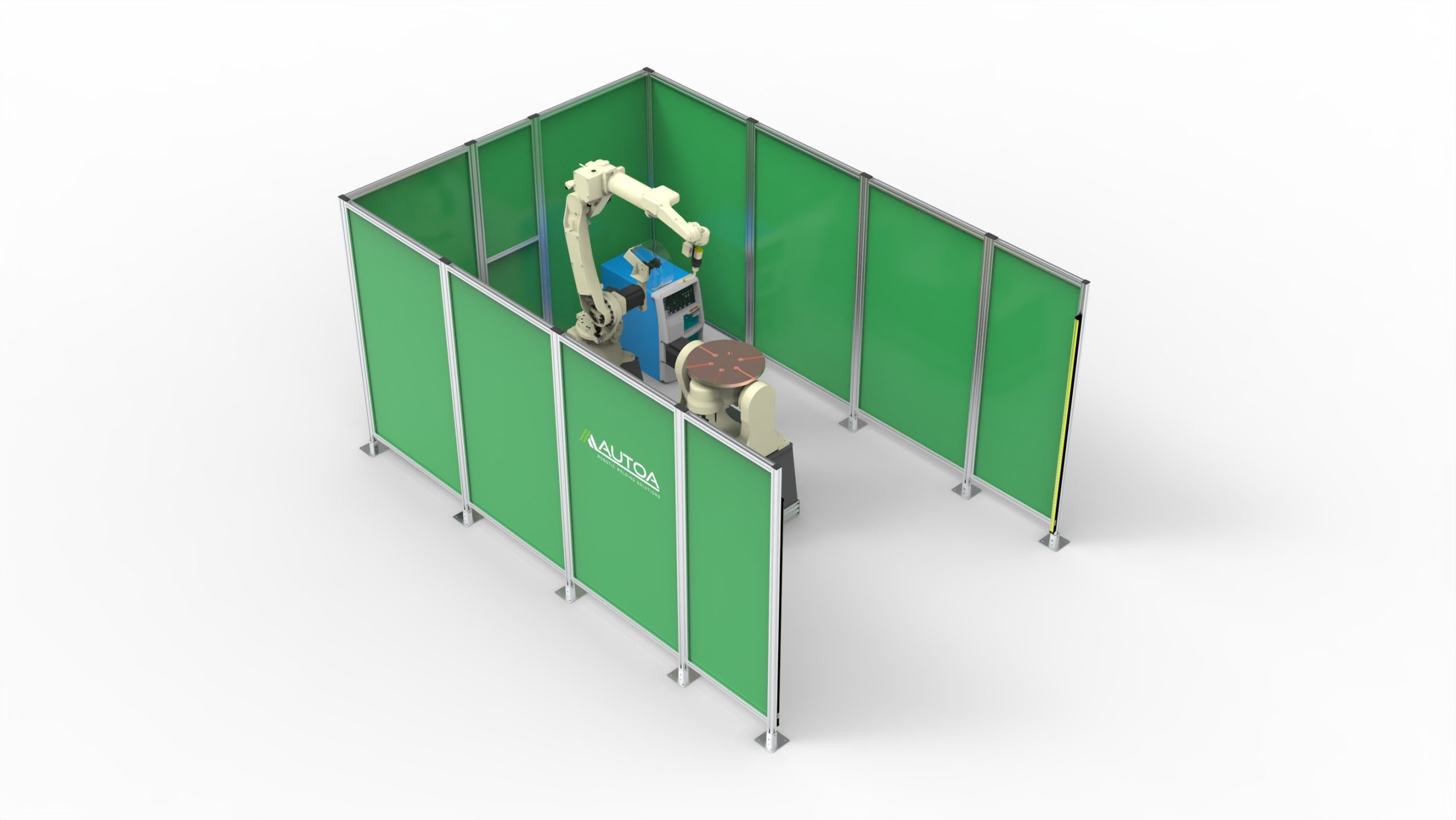

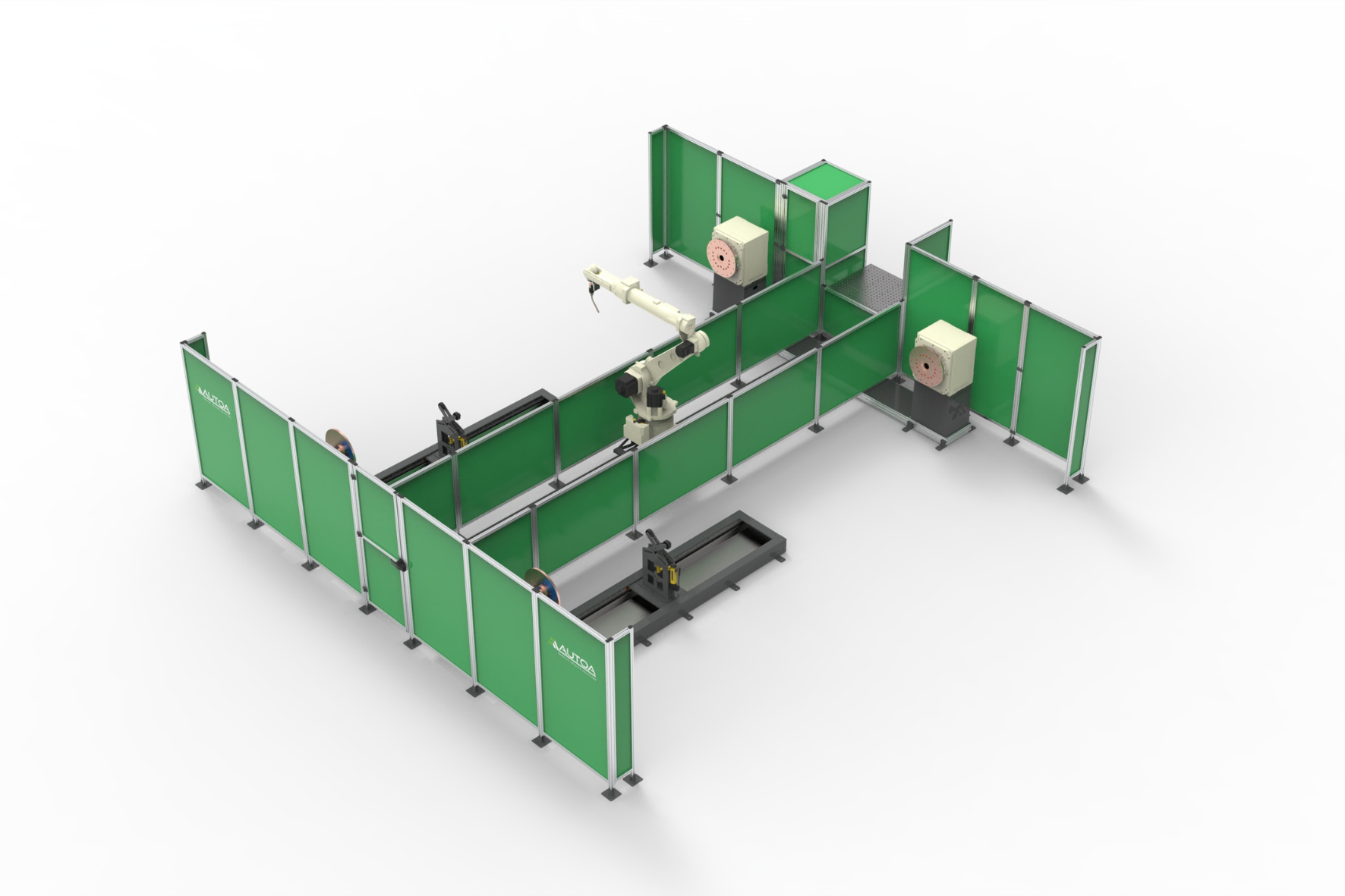

Autoa U Series.

The Autoa U Series robot welding cells are highly efficient workstations designed for large batch manufacturing and high production demands. With a single workstation equipped with headstock and tailstock positioners, the U Series boosts productivity for labour-intensive tasks through advanced robotic technology.

Ideal for improving welding efficiency, reducing errors, and cutting labour costs, the U Series provides a reliable, cost-effective solution. Built for large-capacity welding, it handles demanding tasks with ease, helping you meet production goals and stay competitive.

Standard Robotic Welding Cells

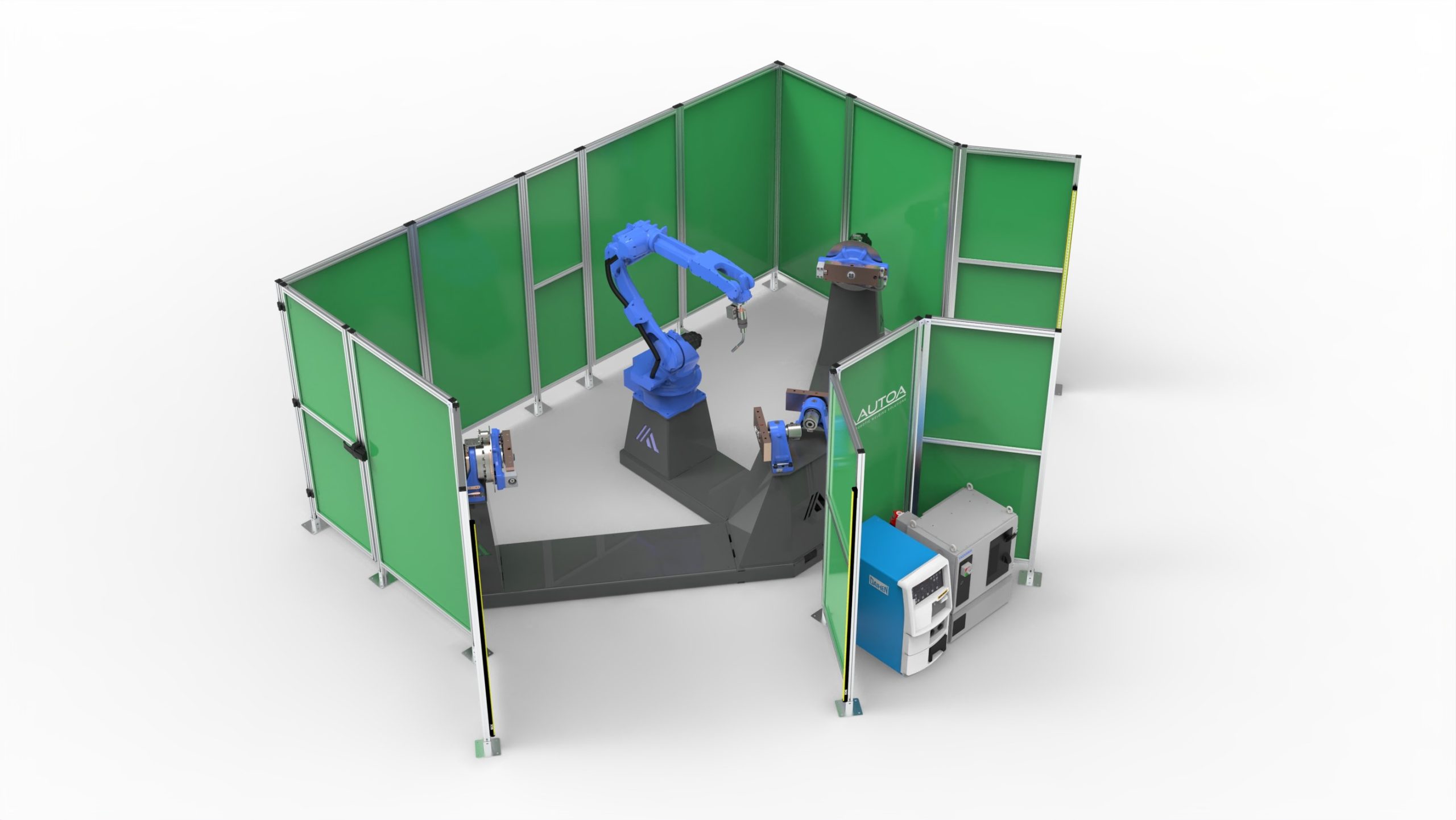

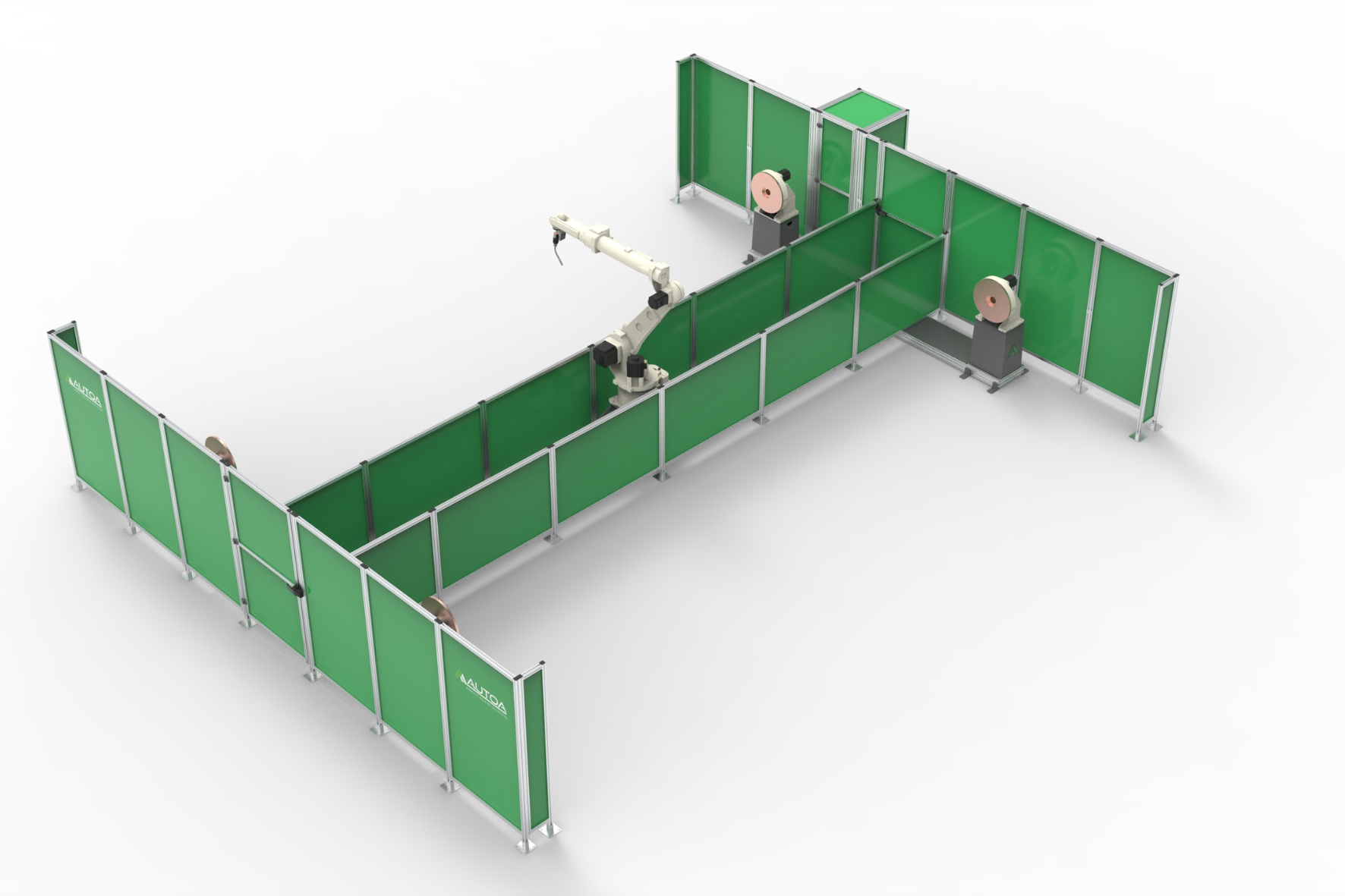

Autoa H Series.

The Autoa H Series robotic welding cells offer unmatched power and performance, perfect for heavy-deposition welding and large-part fabrication. Featuring dual servo-controlled positioners and an H-frame design, the H Series allows operators to prep on one station while the robot welds on another, maximising productivity.

Built for safety and easy integration, the H Series combines advanced robotic technology with precise welding capabilities to handle the toughest tasks seamlessly. Integrating an H Series cell ensures peak productivity, efficiency, and quality—while maintaining a strong focus on worker safety.

Standard Robotic Welding Cells

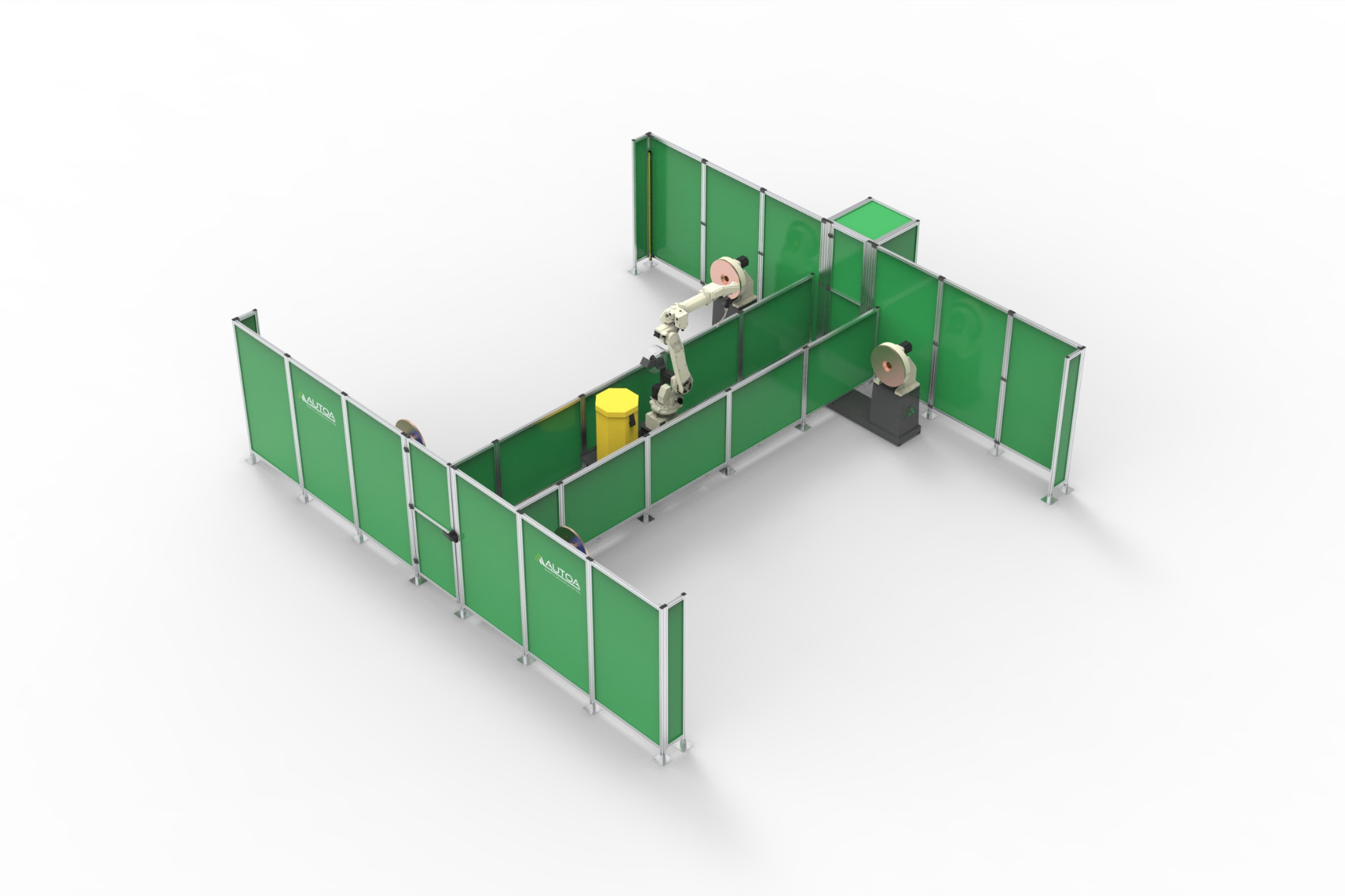

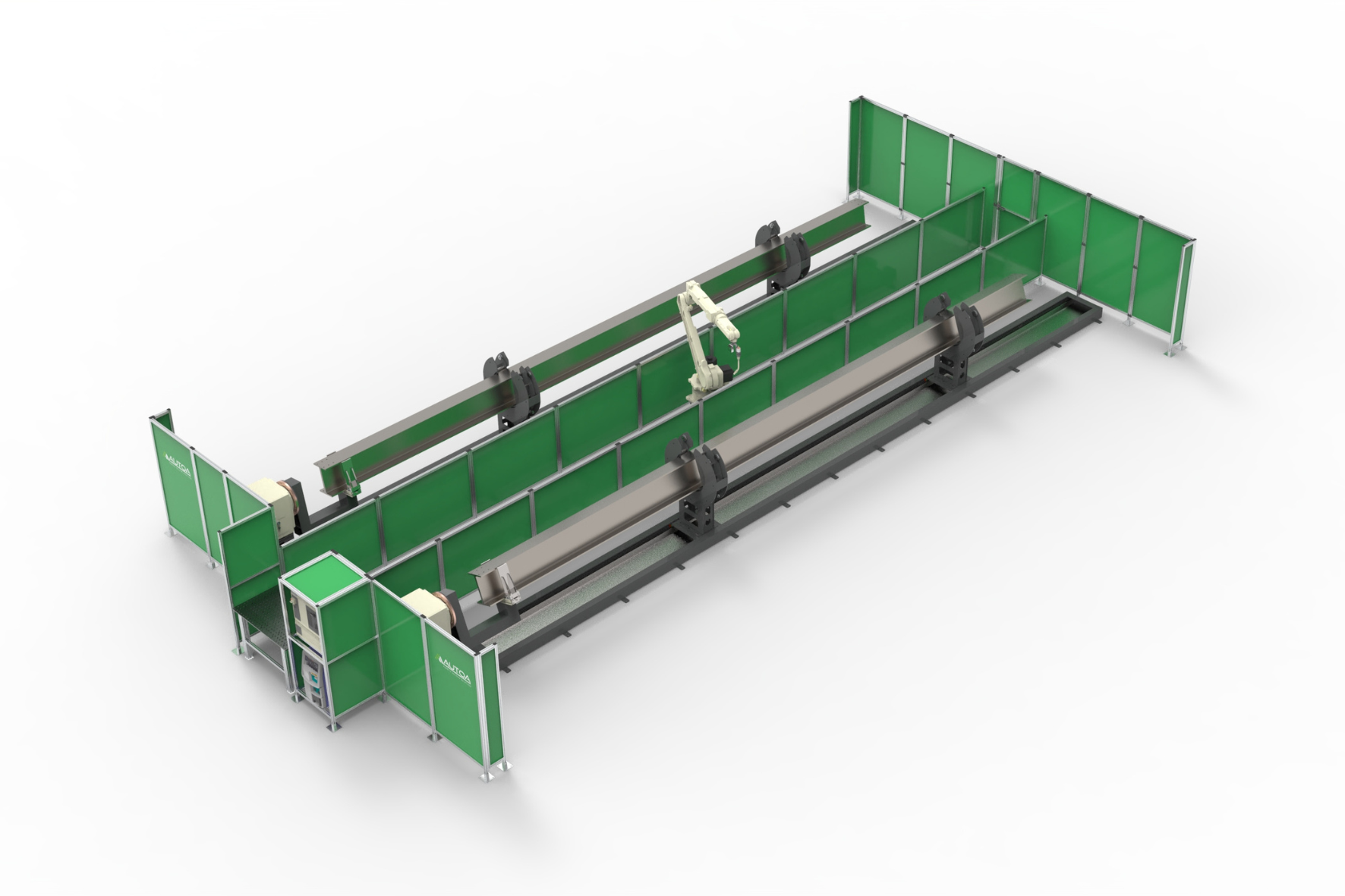

Autoa S Series.

The Autoa S Series robot welding cells are built for maximum efficiency and throughput, featuring a unique robot slider track that adds an extra axis for smooth, coordinated eight-axis motion between the robot and the part. This setup enhances both speed and precision.

With a robust H-cell design and dual servo-controlled positioners, the S Series is ideal for medium to large parts manufacturing. Its adaptable configurations—ranging from two to four workstations—support versatile welding needs, all within a compact footprint. From labour-intensive tasks to heavy deposition welding, the S Series streamlines production, delivering precision and productivity.

Standard Robotic Welding Cells

Autoa-SteelWeld.

The Autoa-SteelWeld robot welding cell is engineered for high-capacity production, ideal for structural steel, pipe work, and open web truss manufacturing. Built for operations handling larger parts, it features a robust robot slider track with eight-axis motion, enabling smooth, precise movement that significantly boosts welding speed and productivity. By reducing the need for extensive manual prep and welding time, it streamlines production and enhances overall efficiency.

Compact yet versatile, the Autoa-SteelWeld offers multiple configuration options to adapt seamlessly to evolving production demands without requiring additional space. By minimising reliance on skilled labor, it simplifies workflows, maximises operational efficiency, and ultimately supports long-term growth and profitability.

Custom Robotic Welding Cells

Looking For A Custom Welding Solution?

When a standard system isn’t the right fit, our custom robotic welding solutions are built to meet your unique production needs. Each custom system is designed from the ground up to optimize output, boost efficiency, and streamline your operations. From initial planning to final implementation, every detail is tailored to achieve seamless, peak performance, giving you a competitive edge and consistent results.

CONTACT US

Start Your Robotic Welding Journey Today.

Let’s talk about how our robotic welding solutions can help your business. As a 100% family-owned company, we’re focused on making robotic welding simple and supporting you every step of the way.