Robotic Welding Comparison Checklists To Find The Best Fit For Your Needs.

Published on 29 April 2025

Choosing the right robotic welding solution is an important step toward improving production, quality, and efficiency.

To help you make a clear and informed choice, Autoa has developed two free Robotic Welding Comparison Checklists — designed to help you compare Autoa’s solutions against alternative providers and software options, side by side.

These practical tools let you assess key features, services, and technologies, giving you a clear overview to support your decision-making.

How Do I Use the Checklists?

Download the checklists below, research your alternatives, and simply tick (✔) or cross (✘) each feature for every supplier or software option you consider. It’s an easy, structured way to clearly compare Autoa with alternative providers.

By the end, you’ll have a clear, fact-based comparison to help guide your decision.

Checklist Overview

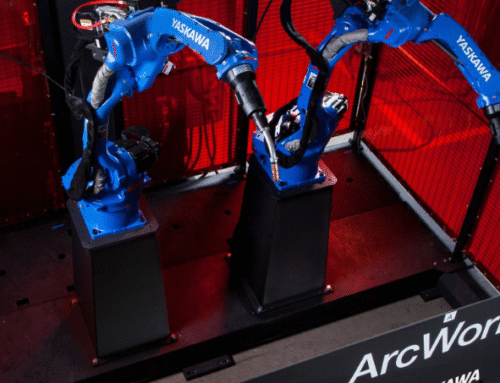

Robotic Welding Provider Comparison Checklist

Assess key areas including:

- Single-source supply of robots, welders, software, and consumables

- Weld trials and testing on your products

- Jig design and support after installation

- Operator training and post-install technical support

- In-house robot servicing and maintenance

Robotic Welding Software Comparison Checklist

Evaluate features such as:

- Scan-to-weld functionality — no CAD models or coding required

- Automatic weld detection and collision prevention

- Plug-and-play program generation

- In-software CAD and weld editing

- Supports welding sensors like Touch Sense and Laser Seam Finding

Want to Dig Deeper?

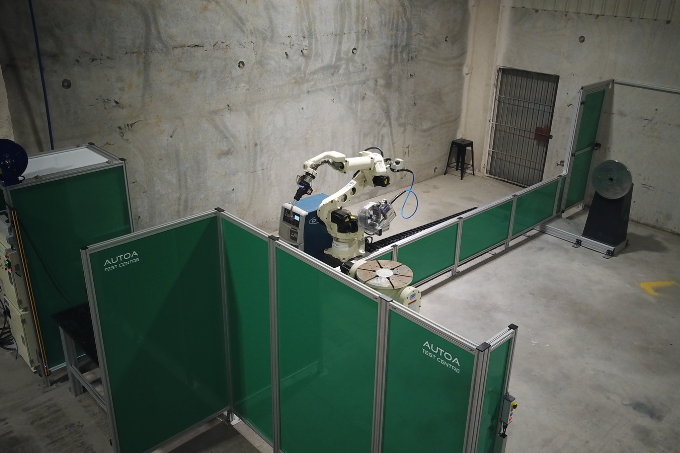

Explore our full range of robotic welding systems and AutoaWeld Software to see how we can support your production goals.

Or contact our team — we’re happy to help you find the right solution for your needs.

hello@autoaweld.com | AU: 1800 573 228 | NZ: 0800 37 55 66

Share this article