AutoaWeld Programming Software: 5 Reasons It Changes the Game.

Published on 18 June 2025

Robotic welding is one of the fastest ways to improve efficiency in fabrication, but traditional programming methods can prevent many manufacturers from taking the first step. The complexity, time investment, and reliance on specialist skills often become barriers.

AutoaWeld Programming Software changes that.

It gives manufacturers a faster, more flexible way to program robotic welding cells using a practical five-step workflow. It simplifies setup, reduces errors, and helps you get more value from every weld.

1. Faster Setup, Less Downtime

AutoaWeld starts with a CAD model of the part to be welded. Files can be imported directly from your design software, making it easy to load new jobs or revisit existing ones. Once the part is placed in the virtual cell, the software automatically detects where welds are needed based on the model.

This removes the need for manual weld definition and gives your team a consistent, reliable setup process. Each job starts from a solid foundation, reducing programming time and the risk of missing welds.

The result is faster changeovers, fewer delays between jobs, and less time spent at the screen. For teams managing multiple part types or short production runs, that time saving adds up quickly.

2. Smarter Weld Planning, Powered by AI

Once welds are identified, AutoaWeld generates torch paths using built-in AI logic. It calculates the ideal travel direction, torch angle, and welding sequence. Collisions are avoided automatically, and movements are optimised for speed and consistency.

This smart path planning ensures each weld is done correctly the first time. Operators don’t need to spend hours solving sequence logic or testing variations. AutoaWeld produces high-quality, repeatable programs aligned with proven welding principles.

This reduces rework and improves overall weld integrity, especially important in structural and production-critical applications.

3. Ideal for High-Mix, Low-Volume Production

AutoaWeld is designed for flexibility. Reprogramming the cell for new parts or short production runs doesn’t require starting from scratch. The software enables quick changeovers using a new CAD file and a few inputs.

For manufacturers dealing with custom jobs, rapid turnarounds, or changing product lines, this agility is essential. It allows teams to respond faster to demand and avoid costly downtime caused by conventional programming methods.

AutoaWeld supports high-mix, low-volume production without compromising weld quality or throughput.

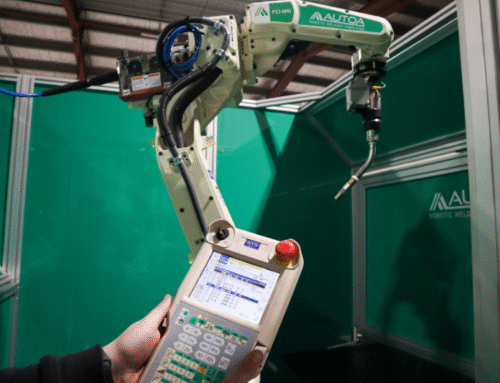

4. No Specialist Programming Required

AutoaWeld eliminates the need for advanced robot programming knowledge. Its step-by-step interface guides users through:

- Importing the CAD

- Detecting and assigning welds

- Planning the weld paths

- Simulating the welds

- Sending the program to the robot

This workflow allows in-house staff to manage programming without relying on external integrators or specialist contractors.

Even team members with limited robotics experience can confidently program jobs and adjust existing sequences. That makes robotic welding accessible to more businesses and gives manufacturers greater control over their own operations.

5. More Welding Time, More Value

Every minute your robot is welding, it’s creating value. AutoaWeld helps maximise this by reducing time spent on programming, testing, and trial runs.

Each weld sequence is simulated in advance, ensuring production starts smoothly and without delays. This reduces waste, lowers the chance of error, and increases productivity.

Manufacturers gain a more predictable process, improved throughput, and a faster return on their robotic investment.

Get Started with AutoaWeld

If programming has been holding you back from robotic welding, AutoaWeld offers a clear path forward. It’s already helping manufacturers across New Zealand and Australia simplify their welding operations and get better results from their robot cells.

hello@autoaweld.com | AU: 1800 573 228 | NZ: 0800 37 55 66

Share this article