5 Key Advantages of Robotic Welding for Manufacturers.

Published on 13 June 2025

1. Increased Productivity and Throughput

One of the most significant advantages of robotic welding is its ability to increase output. Unlike manual processes, robotic systems can operate continuously across multiple shifts without fatigue, delivering consistent performance day after day. This steady pace allows manufacturers to complete more welds in less time, without compromising on quality.

For growing businesses, that increase in capacity often translates into the ability to take on more projects, meet tighter deadlines, and maintain delivery schedules during peak demand. Autoa customers regularly report faster turnaround times and more efficient production workflows after adopting robotic welding systems. One customer saw their weld cycle time drop from 45 minutes to just 7–8 minutes using Autoa’s S-4800 robotic welding cell.

Read more about that result here.

2. Consistent, High-Quality Welds

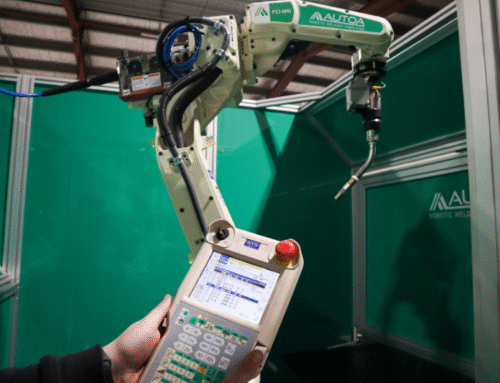

Maintaining consistent weld quality is a challenge in manual operations, where results can vary from one welder to the next. Robotic welding removes this variability by following the same programmed path with precision, ensuring uniform results on every cycle.

This level of consistency is especially important in industries where weld integrity is critical, such as structural steel, transport, and machinery manufacturing. With robotic systems, manufacturers can reduce rework, minimise inspection time, and maintain compliance with demanding standards. Autoa’s robotic welding cells are built to deliver reliable, repeatable welds that meet tight tolerances—day in and day out.

3. Lower Labour and Operating Costs

Robotic welding offers a practical way to reduce operating costs while keeping production teams intact. By automating repetitive welding tasks, manufacturers can increase output, minimise waste, and make better use of materials and consumables.

At GEA Milfos, Autoa’s S-4800 robotic welding cell delivered more than $37,000 in annual savings on a single high-volume component. The investment helped meet rising production demands without increasing labour costs. Staff remained in place and were reallocated to other areas of the business where their skills continued to add value. As more parts were transitioned to robotic welding, the benefits multiplied across the operation.

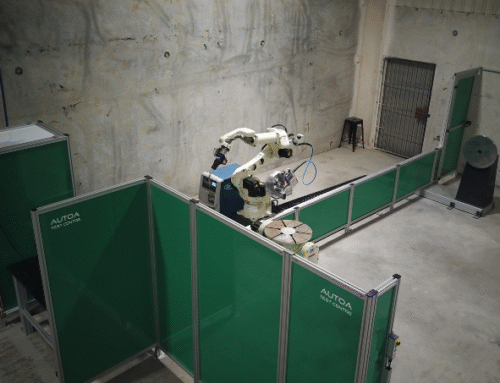

4. Improved Safety for Operators

Welding is physically demanding and often hazardous. Operators face risks from heat, fumes, UV exposure, and repetitive strain, especially during extended production runs. Robotic welding reduces these risks by removing the operator from the immediate weld zone, creating a safer and more controlled environment.

Autoa’s robotic welding systems are built with integrated safety features, including physical guarding, access control, and safety-rated interlocks. When paired with effective fume extraction tools, exposure to airborne contaminants is significantly reduced. These measures support compliance with health and safety regulations while creating cleaner, safer conditions on the shop floor.

With less time spent on high-risk tasks, operators can focus on supervision, quality assurance, and maintaining efficient production flow.

5. Flexible Integration with Existing Processes

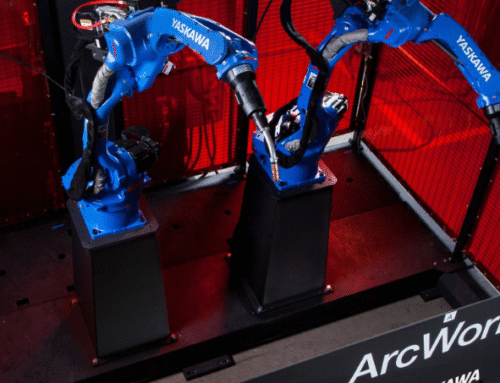

Robotic welding systems are designed to integrate into a wide range of production environments. Whether you’re managing high volumes, short runs, or mixed-part workflows, flexibility is essential to maintaining efficiency and adapting to demand.

Autoa provides welding solutions tailored to suit your operation, ranging from fully automated cells to collaborative robot setups. With AutoaWeld’s offline programming tools, new weld paths can be created, tested, and refined without stopping production. This allows faster changeovers, reduced downtime, and easier adjustments when schedules shift or new product variants are introduced.

Rather than requiring a complete overhaul, robotic welding enhances your existing processes and adds capability where it’s needed most.

Robotic Welding: A Smarter Way to Build and Grow

Robotic welding is helping manufacturers improve performance across every part of their operation. From increased productivity and consistent weld quality to safer workflows and long-term cost savings, the benefits are both practical and proven.

Across Australia and New Zealand, manufacturers are using robotic welding to handle growing workloads, strengthen output reliability, and make better use of their teams and resources. It’s not about replacing people, it’s about enabling them to do more with the right tools in place.

Explore our case studies to see how manufacturers are using robotic welding in real-world settings to improve efficiency, output, and overall performance.

hello@autoaweld.com | AU: 1800 573 228 | NZ: 0800 37 55 66

Share this article