Autoa coweld Speeds up Manufacturing Process for luge cart world

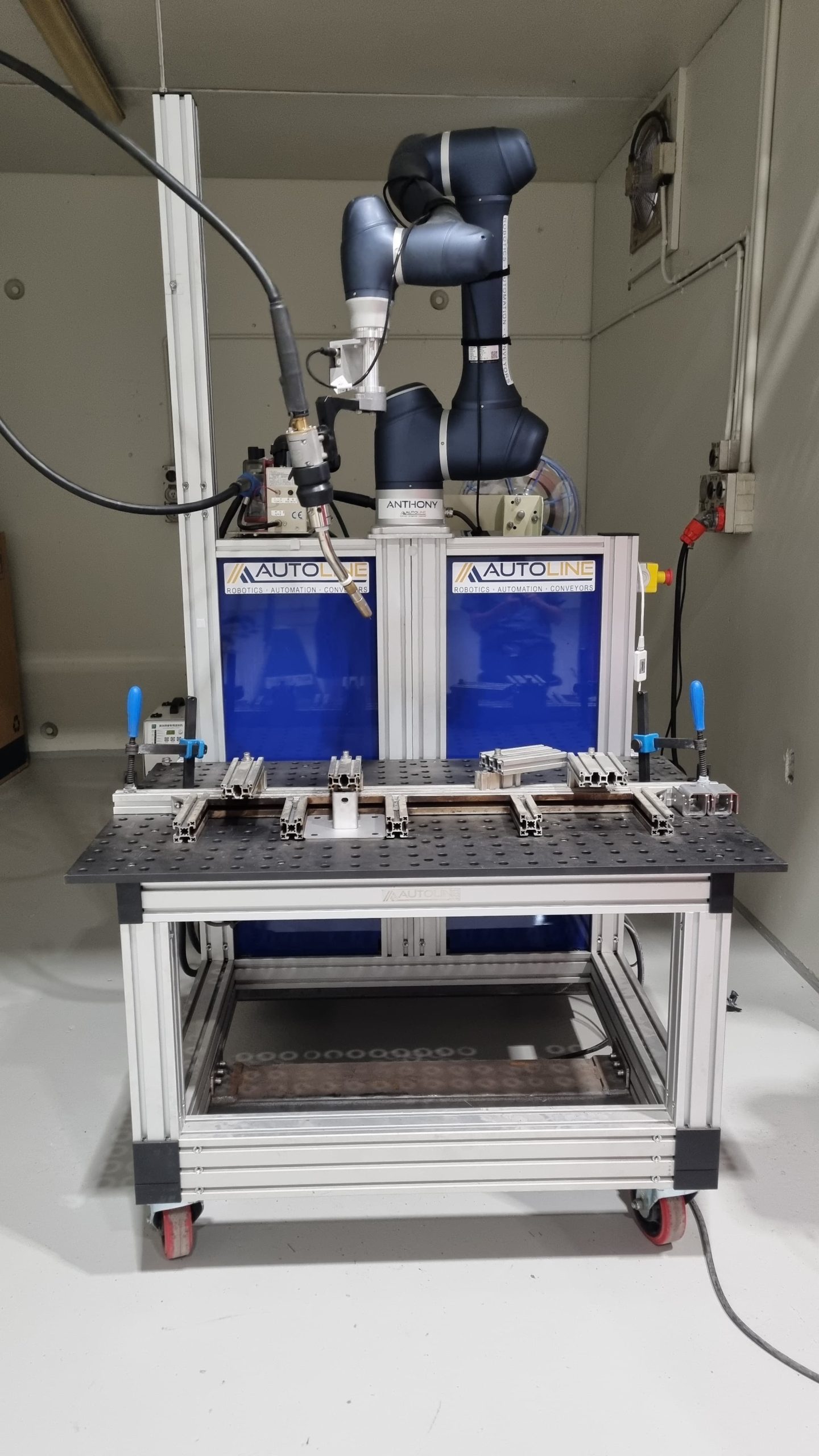

Company: luge cart world | Cell: autoa coweld

EQUIPMENT

- 1 x Doosan A0912 Collaborative Robot Arm

- 1 x Doosan Controller and Teach Pendant

- 1 x OTC Daihen P500L Welding Power Source

- 1 x OTC Daihen Wire Feeder

- 1 x OTC Daihen 350a air cool torch and welding consumables

TESTIMONIAL

Investing in a Autoa CoWeld, enabled Luge Cart World to innovate, speed up their manufacturing process and ramp up their competitive advantage.

Based in one of the most adventurous nations in the world – New Zealand – Luge Cart World is a world-class provider of luge carts, safety barriers and return systems, as well as consultancy, infrastructure, planning and track design.

Luge Cart World chairman Les Osbourne says they were previously outsourcing all their welding and started looking into collaborative robot welders as a way to make the business more efficient.

Far from slowing down the process, bringing the welding in-house has been far more efficient than outsourcing it, Les says.

“Not only has it sped up our manufacturing process, it gives us far more control over production management, which saves us time and ultimately, saves us money.”

Collaborative welding robots (Cobots) are a low-cost and effective way to get started with welding automation, allowing manufacturers to increase capability quickly and easily.

After some excellent training provided by Autoa, Luge Cart World has found the unit very easy to operate, Les says.

Engineering firms that have low-volume, high-mix manufacturing, such as Luge Cart World, will find Cobots to be an extremely cost-effective solution.

“It was definitely worth the investment,” Les says. “The Autoa CoWeld is a valuable asset.”

Contact Us

Start Your Robotic Welding Journey Today!

Let’s talk about how our robotic welding solutions can help your business. As a 100% family-owned company, we’re focused on making robotic welding simple and supporting you every step of the way.