Customer Support

Keep Your Welds Going Strong.

We’re with you every step of the way on your robotic welding journey. At Autoa, we understand how crucial it is to keep your equipment running at peak performance. That’s why we’re dedicated to helping you maximize its potential and minimize downtime.

Our team of highly trained and certified robot technicians are always available for both on-site visits and remote support. Whether it’s troubleshooting an issue, performing routine maintenance, or optimizing your systems, we’re here to ensure your operations continue to run smoothly and efficiently.

Robot Servicing

Servicing That Never Misses A Weld.

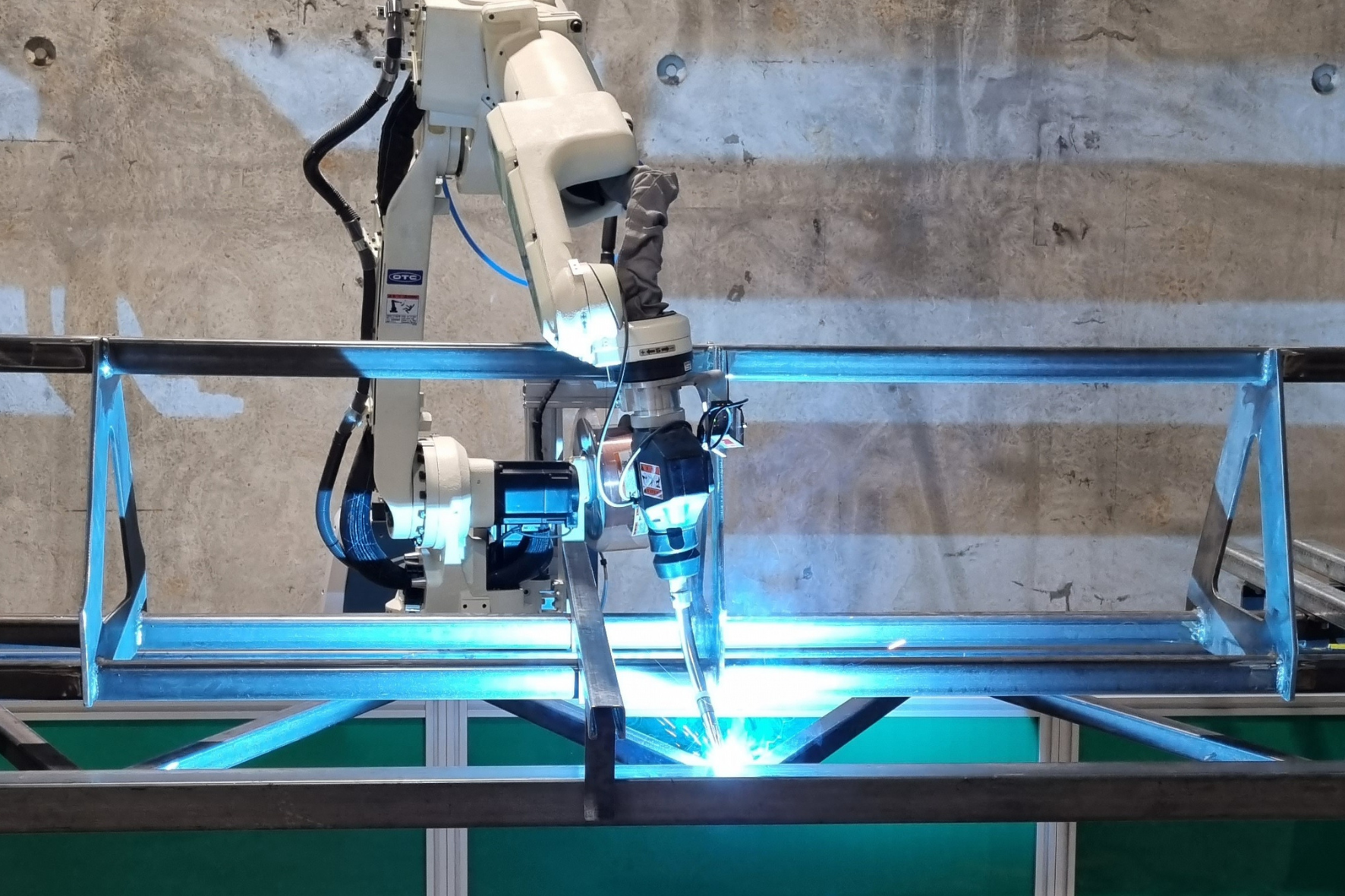

Keep your welding robots performing at their best with expert maintenance that prevents downtime and extends equipment life. Autoa provides comprehensive servicing solutions—covering diagnostics, part replacements, and preventive maintenance—to ensure your robotic welding systems operate in peak condition and deliver maximum efficiency.

Our skilled team of robot technicians, including trained service and application engineers, brings years of experience with Yaskawa, OTC Daihen, and Doosan robotic welding equipment. From routine servicing to emergency repairs, our reliable service keeps your welding robots running smoothly and productively.

We currently maintain and service over 300 robotic welding systems across Australia and New Zealand, specializing in a wide range of welding applications, including MIG/MAG welding for ferrous and nonferrous metals and plasma welding for precision work.

Robot Maintenance: Key Guidelines

To keep your robotic welding equipment in peak performance, manufacturers recommend servicing every two years or 6,000 servo hours. Our typical service includes:

- Full lubrication of critical components.

- Replacement of encoder backup batteries to prevent data loss, avoid reprogramming, and reduce downtime.

With Autoa’s expert servicing, your robotic welding systems will stay in top condition, ensuring maximum productivity and minimal disruption to your operations.

Robot Operator Training

Training That Sparks Precision In Every Weld.

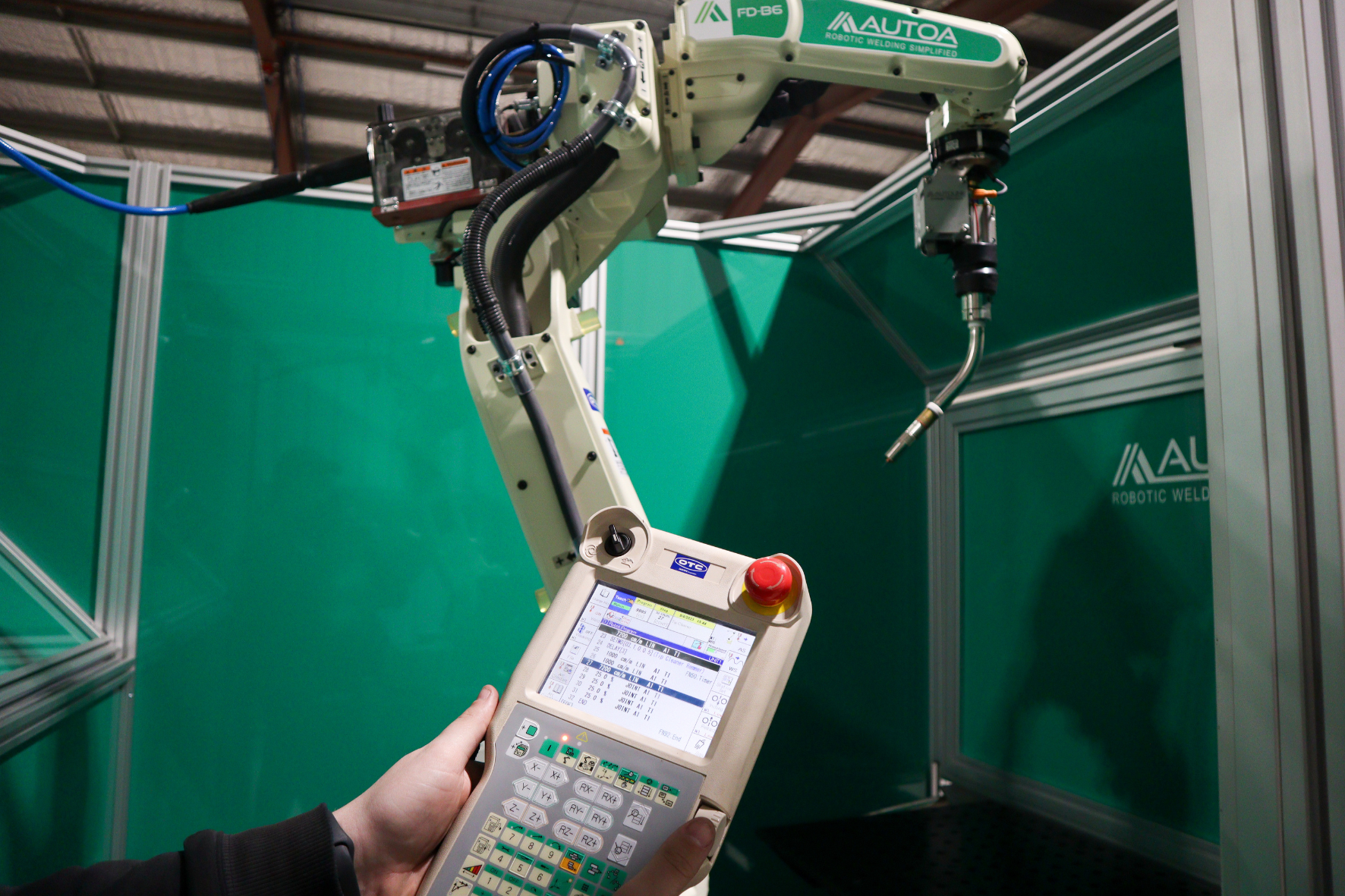

We understand that well-trained operators are the key to maximizing the performance of your robotic welding systems. That’s why we offer comprehensive, hands-on Robot Operator Training designed to equip your team with the technical skills and confidence needed to operate robotic welding equipment effectively.

Our courses, led by expert robot technicians and programmers, are tailored to suit your specific equipment and application. Whether you require standard training modules, modified content, or fully customized courses, our goal is to ensure your operators have the knowledge to get the most out of your robotic systems.

Why Choose Autoa’s Robot Operator Training?

Maximise Your Return On Investment (ROI).

Training your operators leads to better equipment performance, minimized downtime, and optimized productivity. Autoa’s Robot Operator Training is designed to boost your return on investment by:

- Empowering your operators with practical, job-specific skills.

- Reducing costly errors and equipment downtime.

- Improving process efficiency and safety.

We provide follow-up training and support to ensure your team continues to build on their skills. Whether your operators are new to robotic systems or seasoned professionals looking to refine their techniques, our training is structured to provide value at every level of experience.

For more information on scheduling, training session details, or pricing, please contact our support team to discuss how we can help your team master robotic welding and maximize your productivity.

CONTACT US

Support You Can Always Count On.

Whether you have one robot or hundreds, we’re committed to maximizing your robotic welding performance, minimizing costs, and delivering expert support throughout your equipment’s lifecycle to ensure reliable, efficient operation at all times.