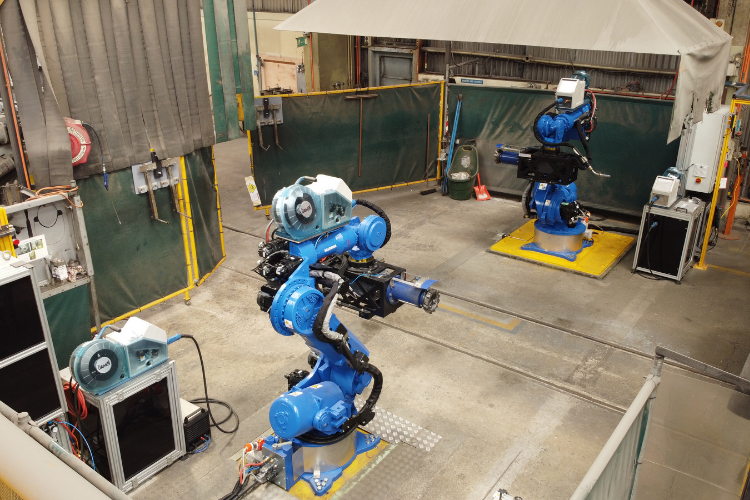

RIO TINTO’S ROBOTIC WELDING SUCCESS

Company: Rio Tinto | Cell: Custom Cell

EQUIPMENT:

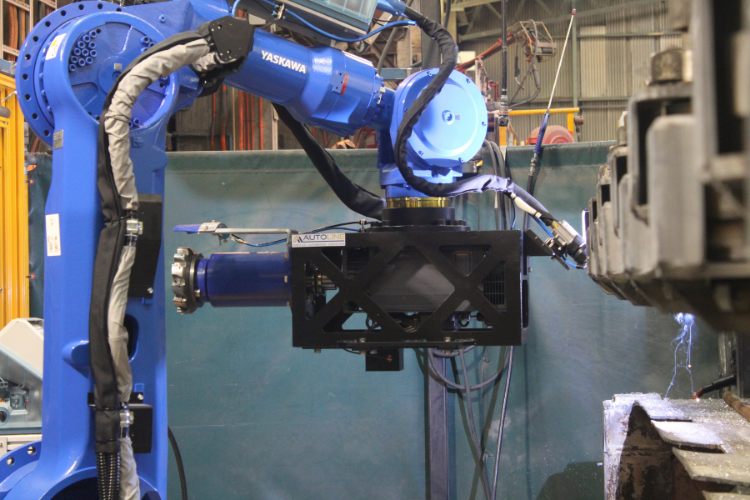

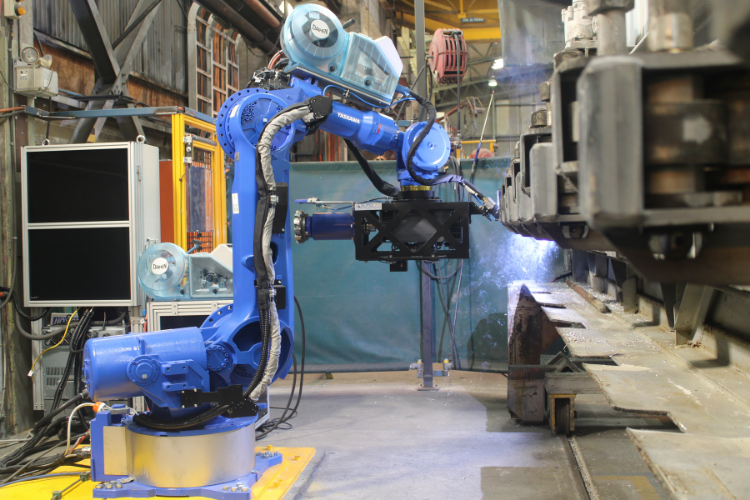

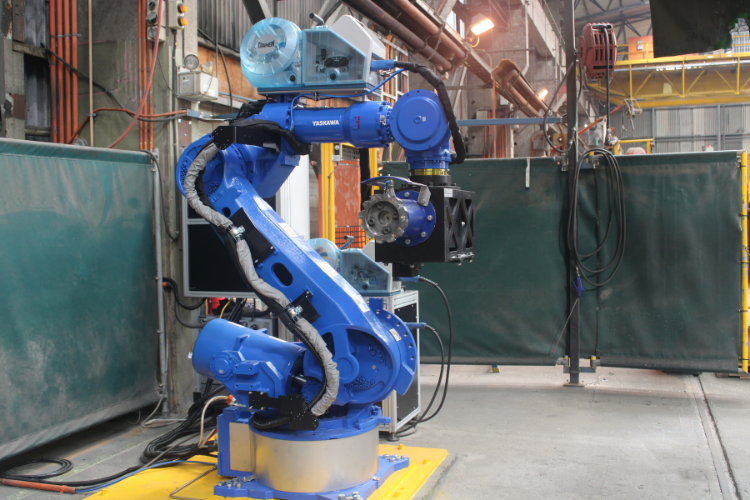

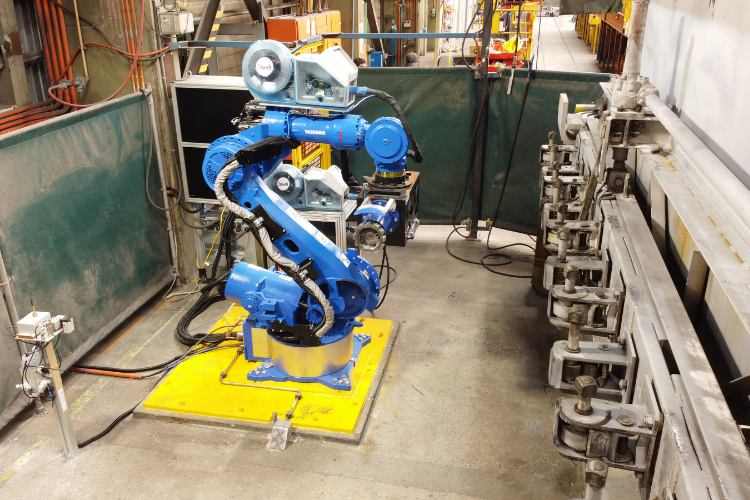

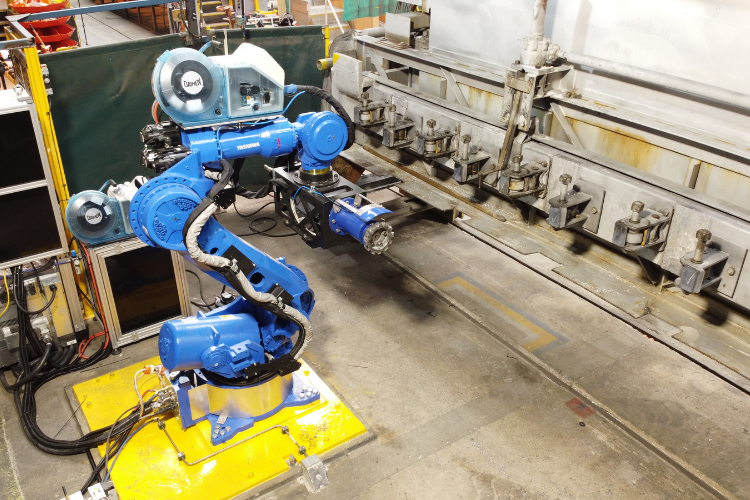

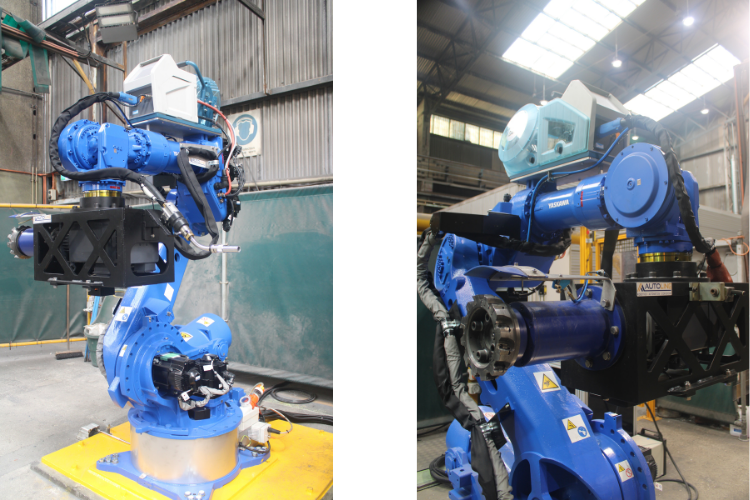

- 2x Yaskawa Motoman GP280 Robot with YRC1000 Robot Controller and Teach Pendant

- 2x OTC Daihen Welbee P500L Welding Power Source

- 2x OTC Daihen Manual Welding with Auto Handover

- 2x Milling Systems

- 2x Cutting Lubricant Systems

- 2D Laser Scanning

- Custom Built HMI system

- 1x Tip Cleaning Station

- 1x Safety guarding and interlocking system for cell access using RFID tags

TESTIMONIAL

Rio Tinto’s Tiwai Point has always been about its people, according to long-serving staff member Paul Cavanagh, and that’s the driving factor in a recent upgrade and doubling of its robotic welding equipment.

“It’s about keeping people away from the load. People and safety first,” he says. Tiwai Point has used robotic welding since 1995 and this is the second upgrade since 2008 – but this time the number of robots has doubled, along with the addition of an extra robot for loading heavy steel pins, a previously manual task. Cavanagh, the crew leader for the rodding process, says recent uncertainty was in the rearview mirror, with the smelter securing a 20-year deal for electricity supply.

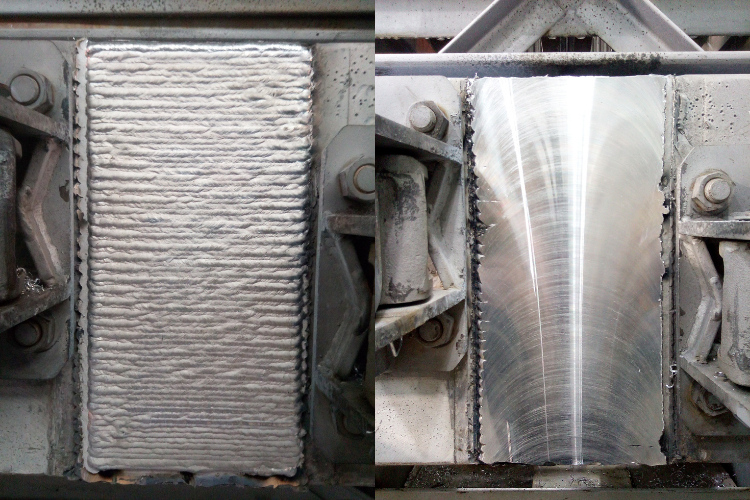

It was clear for some time there was a need to replace the old system used to weld anode rods used in aluminium production. Around 550 are processed in a 24-hour period. In the smelter’s reduction process an anode is in the reduction cell for 24 days where stubs can be damaged – either through process related events, or simple age. Rods are rejected into the rod repair area where the robot can weld all four stubs if required.

“Aluminium remains a key structural material, used in multiple industries around the world, and Tiwai Point is New Zealand’s only smelter.”

Contact Us

Start Your Robotic Welding Journey With Us Today!

Let us help build a solid business case to show how our robot welding solutions can benefit your business. As a 100% family-owned company, we’re passionate about improvement and ensuring your satisfaction throughout your robot welding journey.