Structural Steel RobotiC Welding

Configurations To Suit Your Steel.

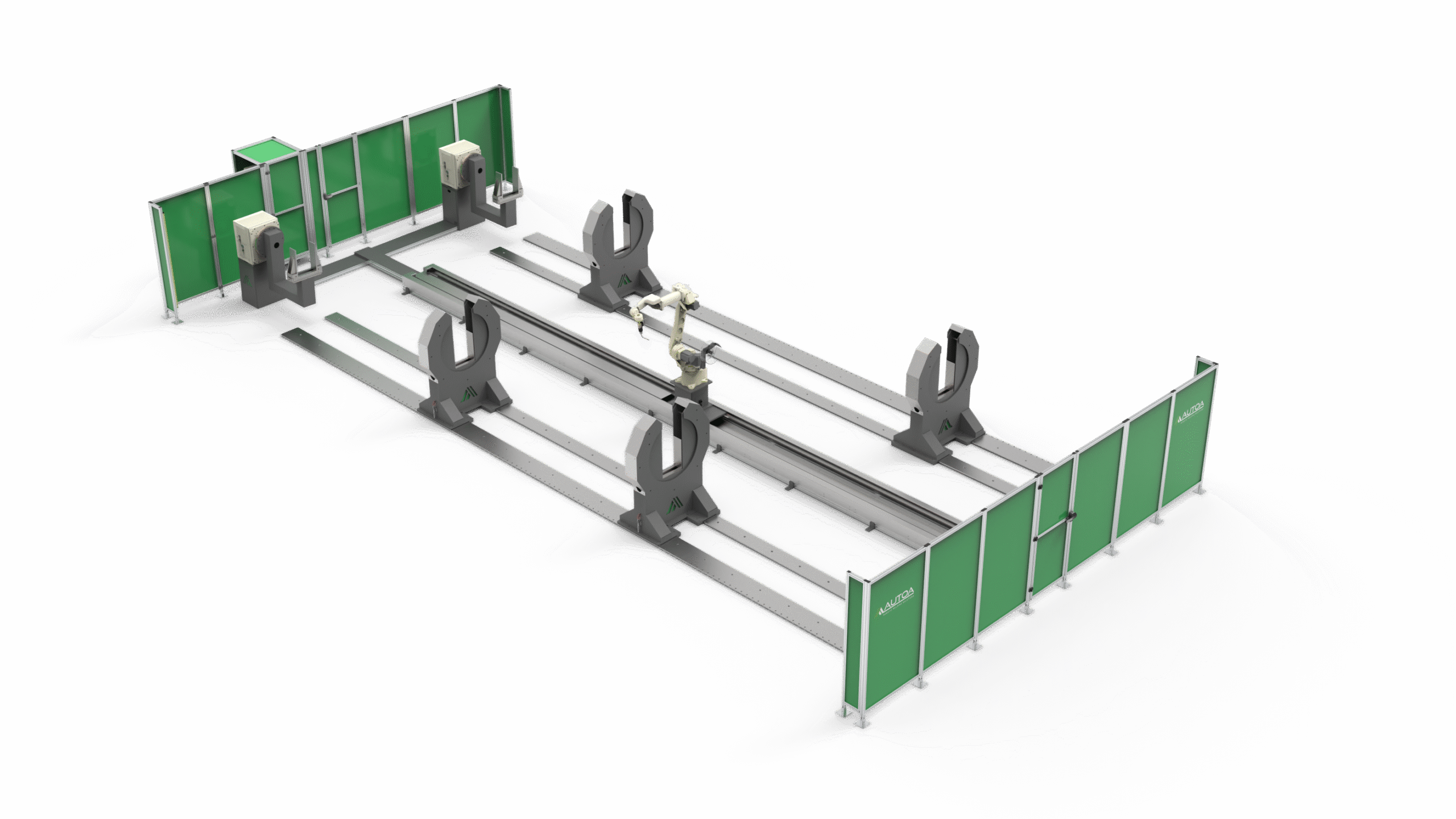

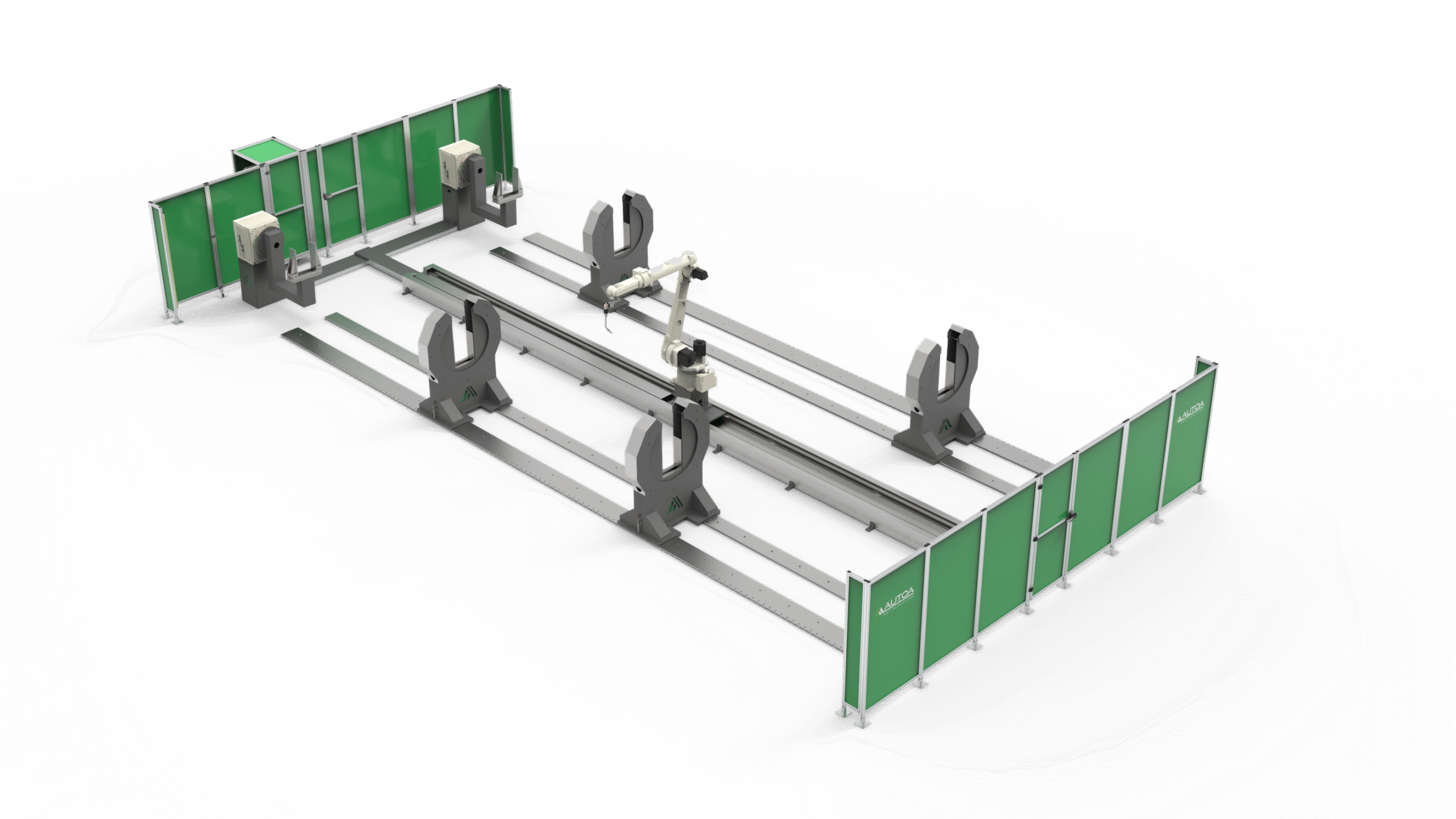

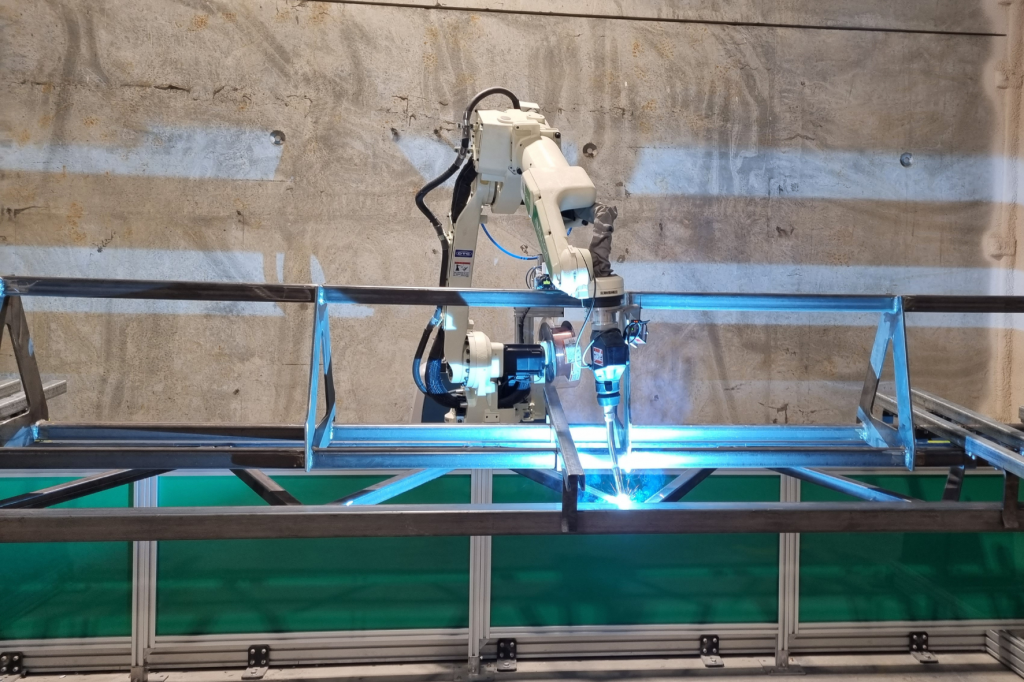

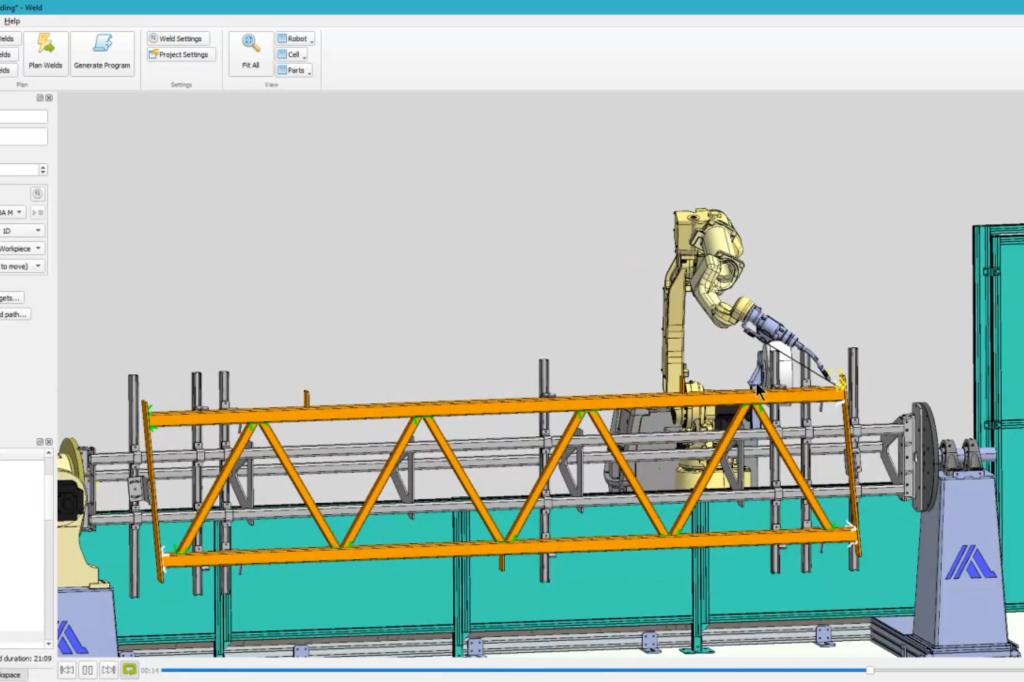

Autoa-SteelWeld is a robotic welding system purpose built for structural steel fabrication. It delivers fast, accurate and repeatable welds on beams, columns, trusses and more, helping fabricators reduce labour, simplify complex welding tasks and improve weld consistency.

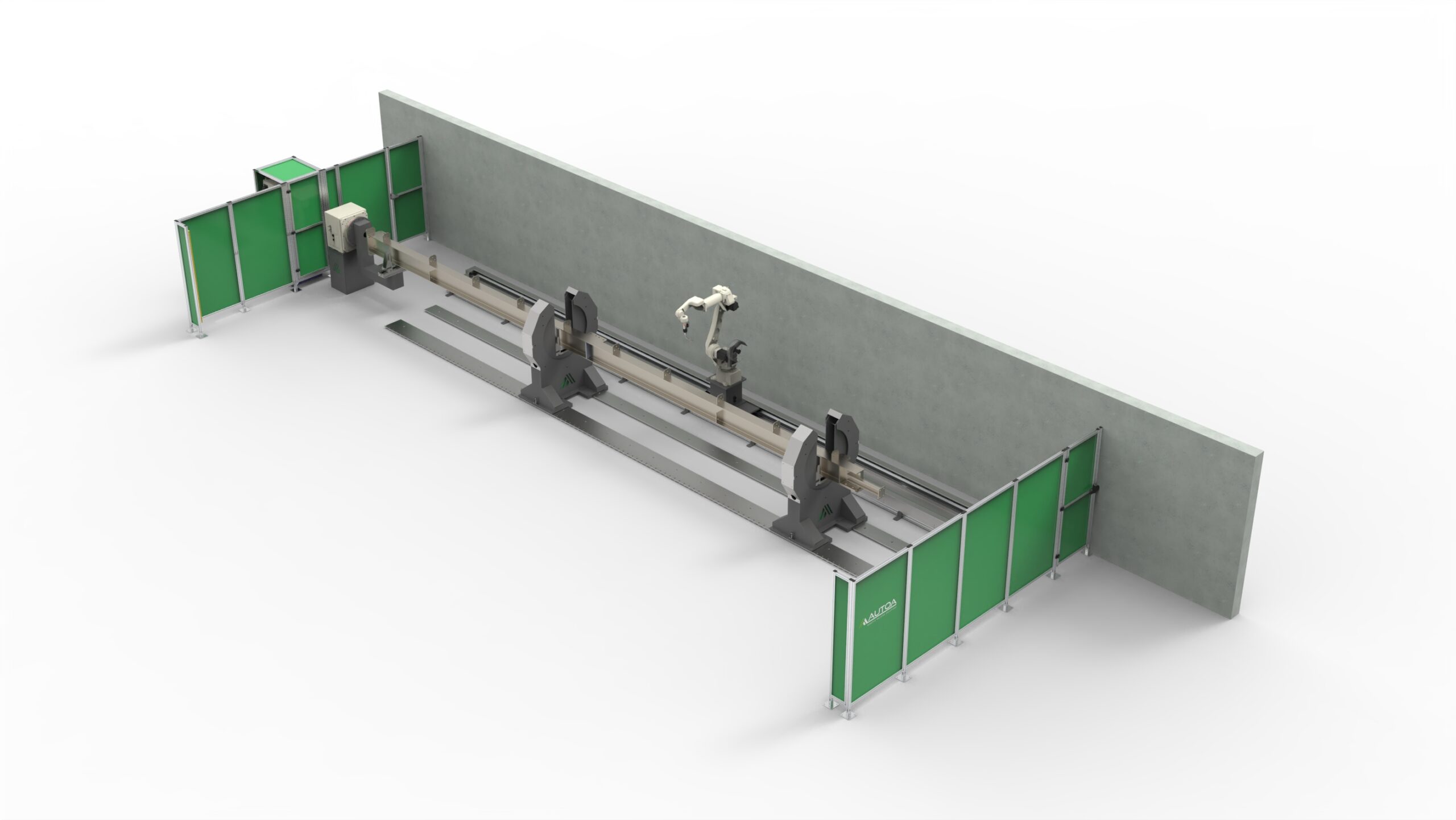

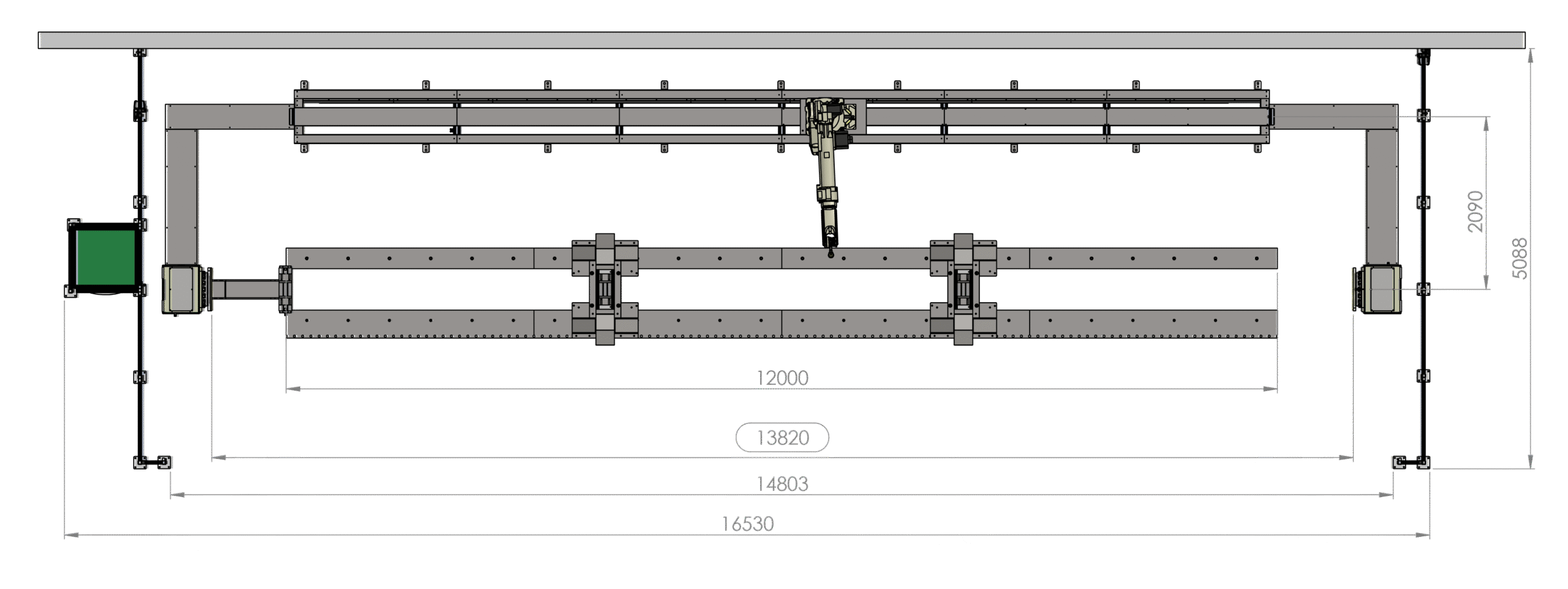

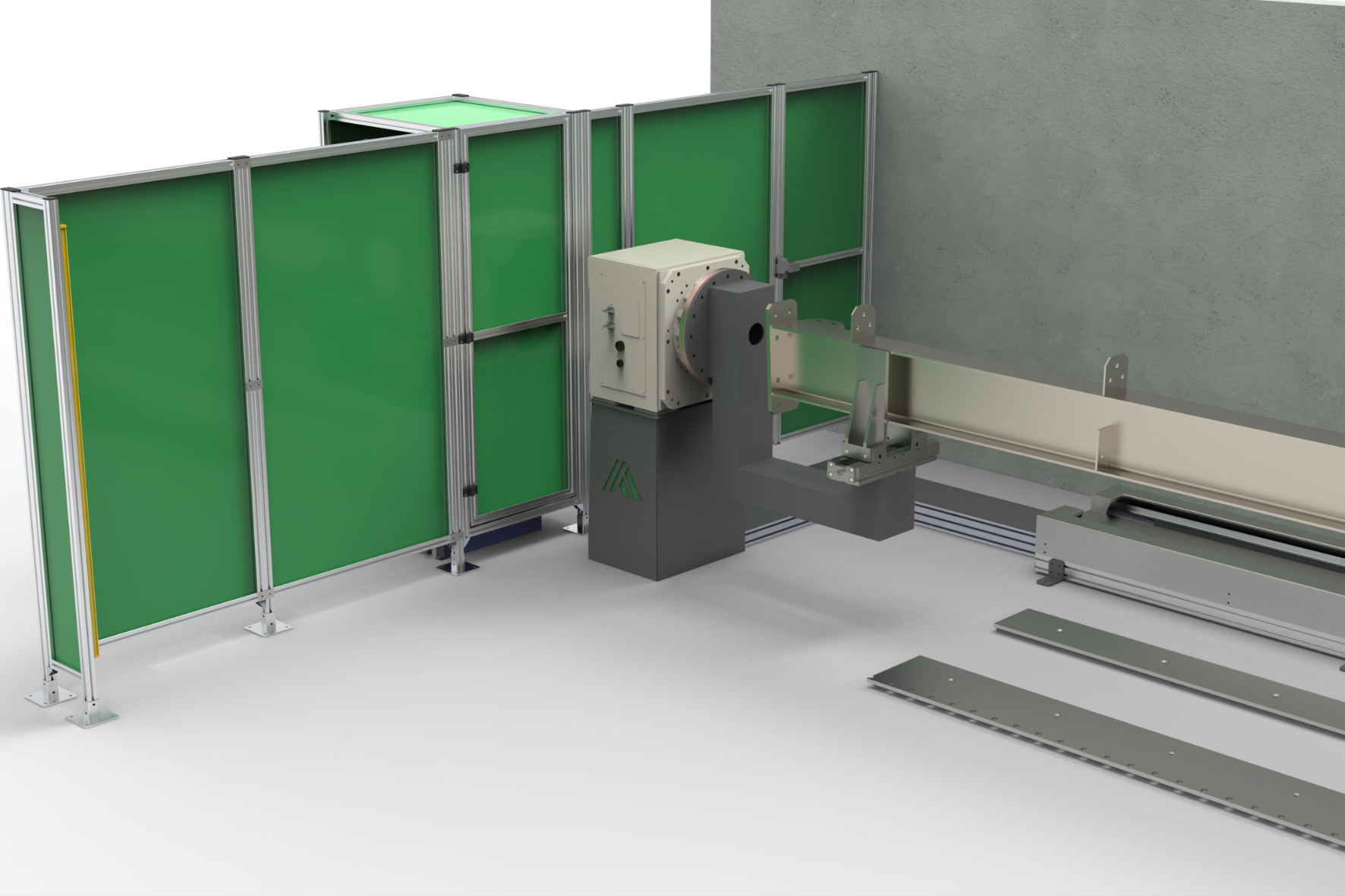

Compact footprint for smaller workshops or jobbing environments. Ideal for standard structural parts and accessory welding.

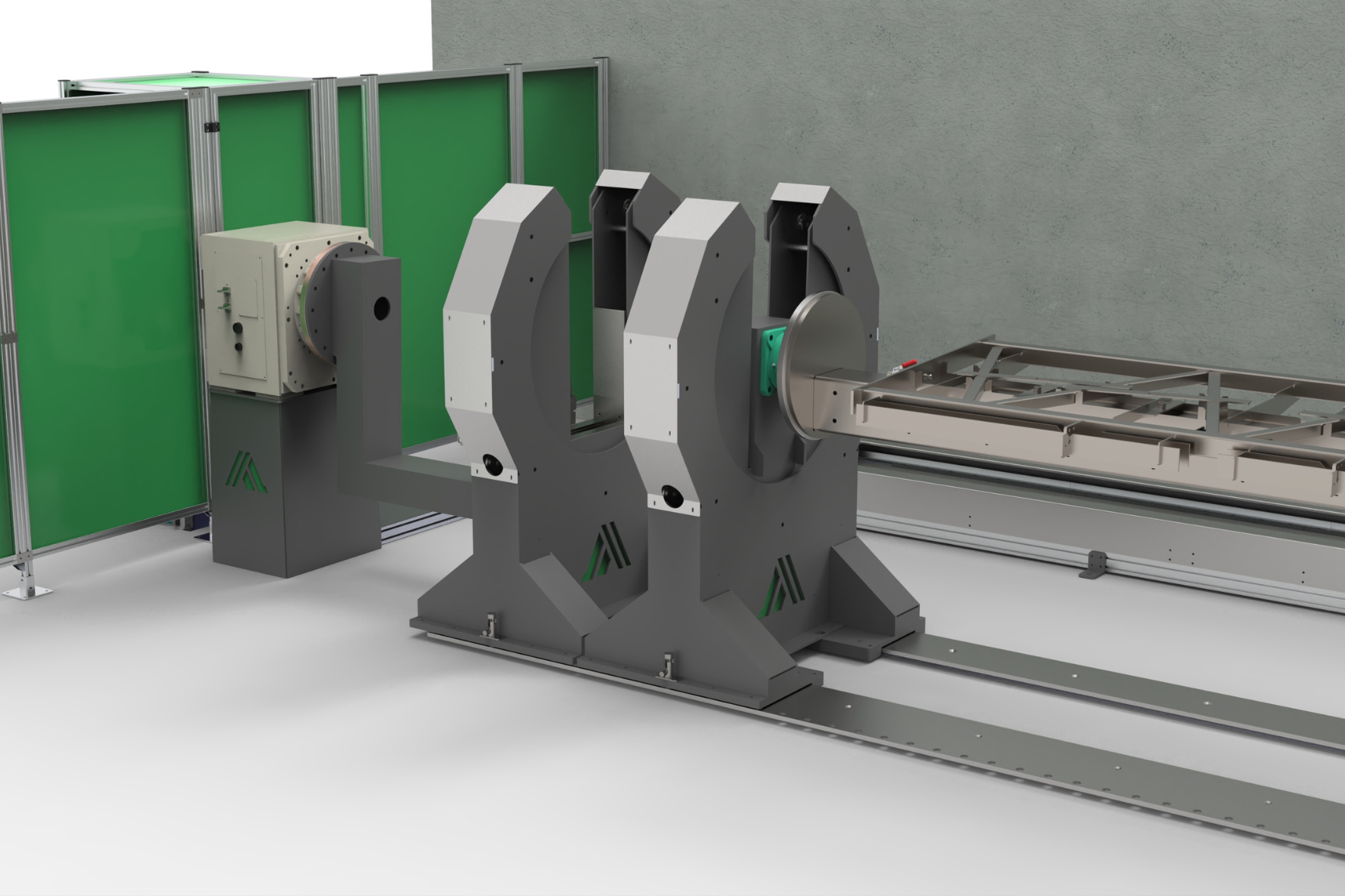

Extended reach for larger assemblies and longer components. Great for fabricators working on heavy or oversized steel.

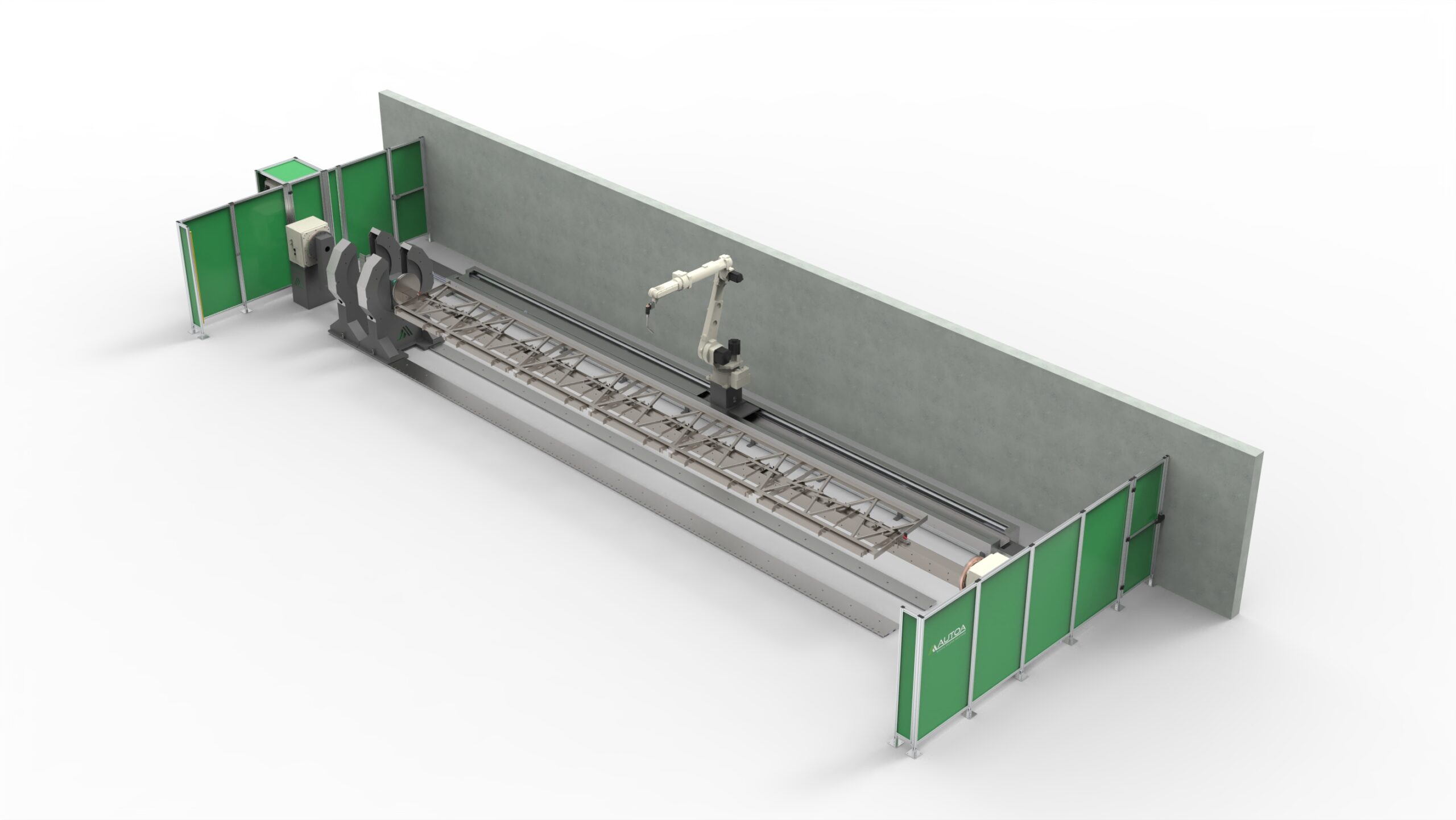

Two-sided operation for continuous workflow. Weld on one side while loading or prepping on the other — ideal for high-throughput operations.

Two-sided operation for continuous workflow. Weld on one side while loading or prepping on the other — ideal for high-throughput operations.

Autoa-Steelweld features

Features That Refine Every Weld.

Designed for Steel Manufacturers

Structural Welding Capability.

Designed to handle a wide range of structural steel components, Autoa-SteelWeld adapts to everything from standard beams and RHS sections to complex trusses and multi-accessory assemblies. It maintains consistent weld quality across diverse part profiles, making it ideal for both repetitive production and project-based fabrication.

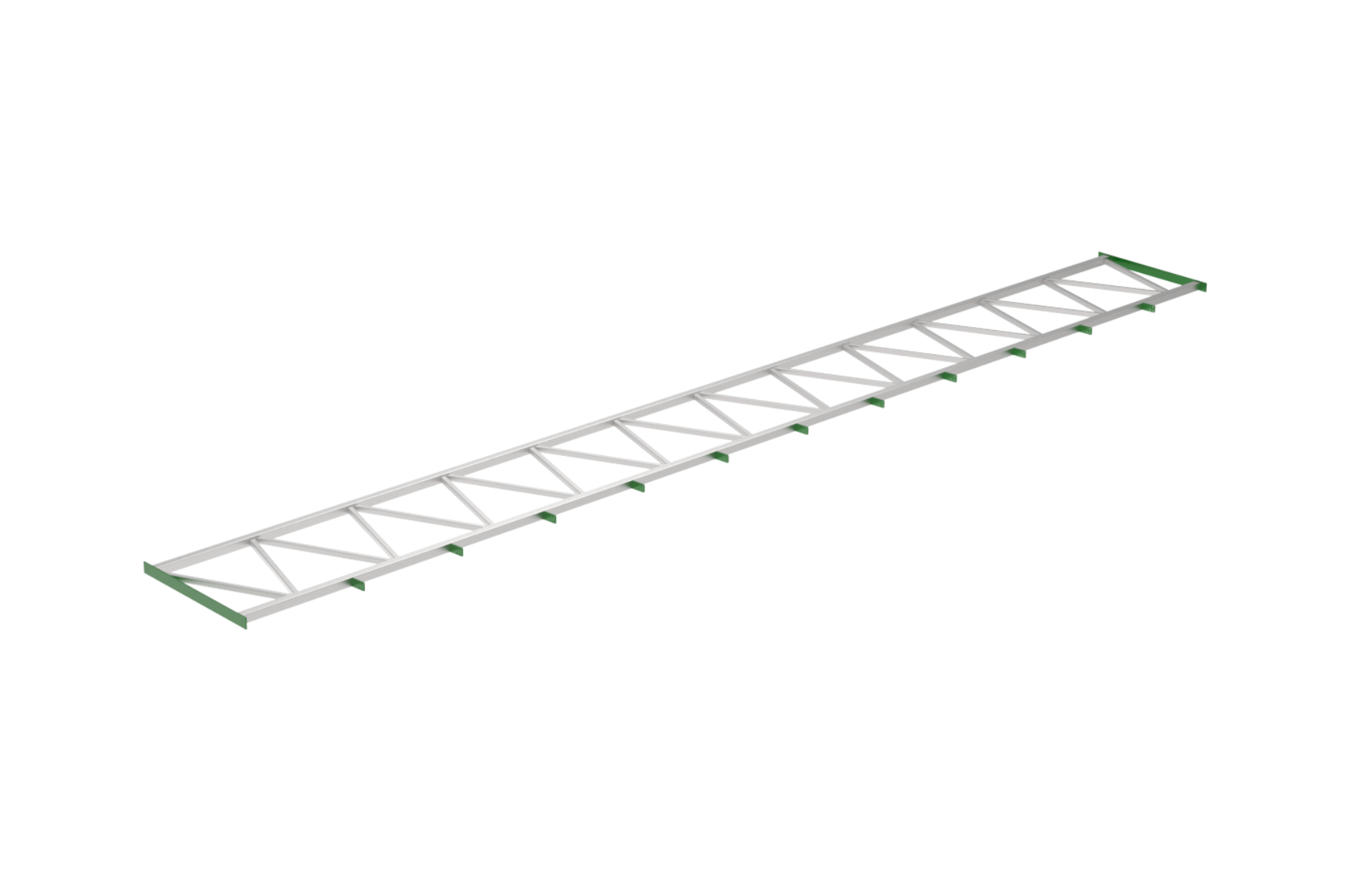

Truss Weldment – Welded bracing and node connections for light or heavy trusses.

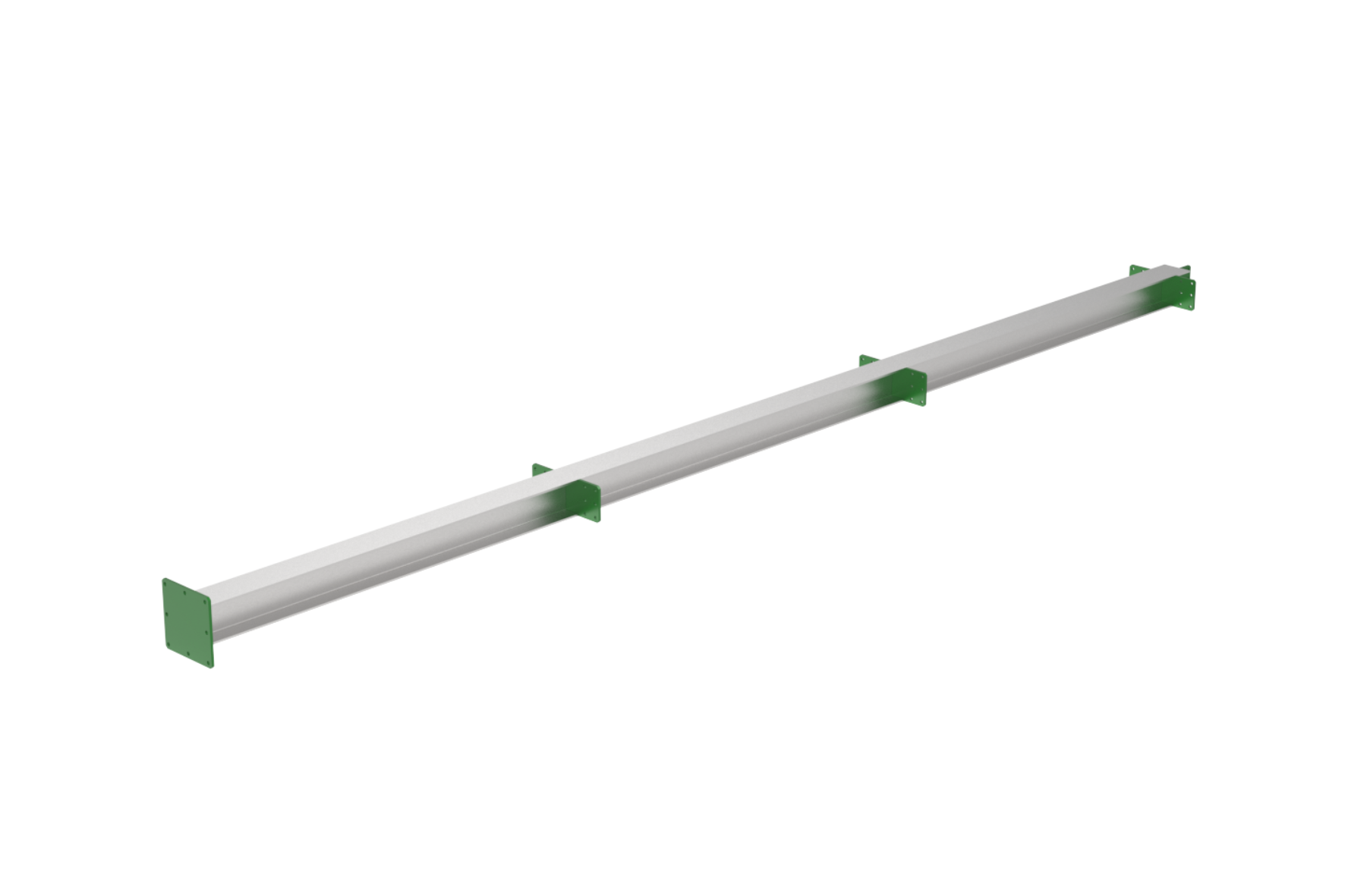

RHS / SHS Section – Welding of square and rectangular hollow sections for structural use.

Beam with End Plates – Welding of universal beams or columns with fabricated end plate connections.

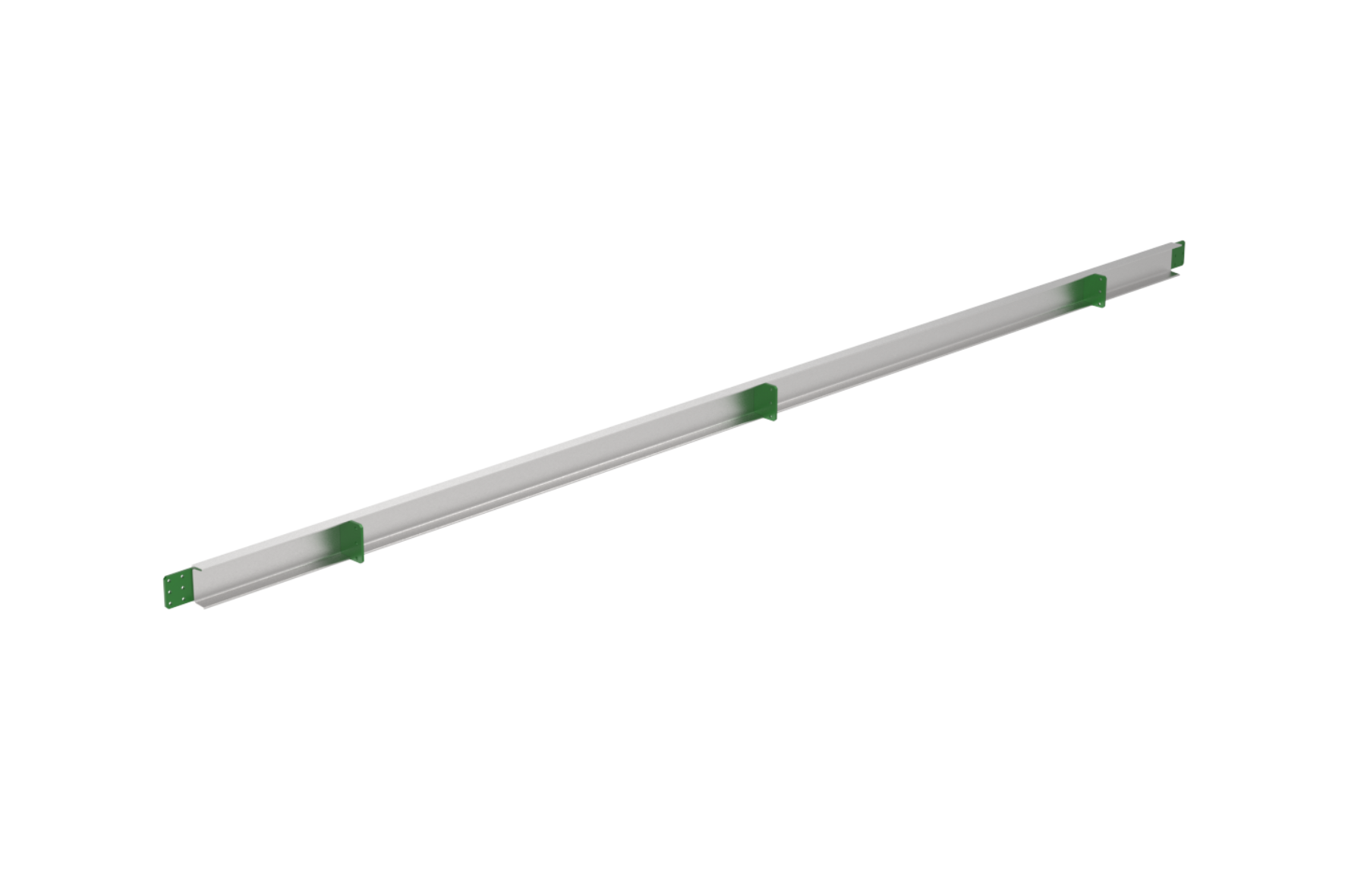

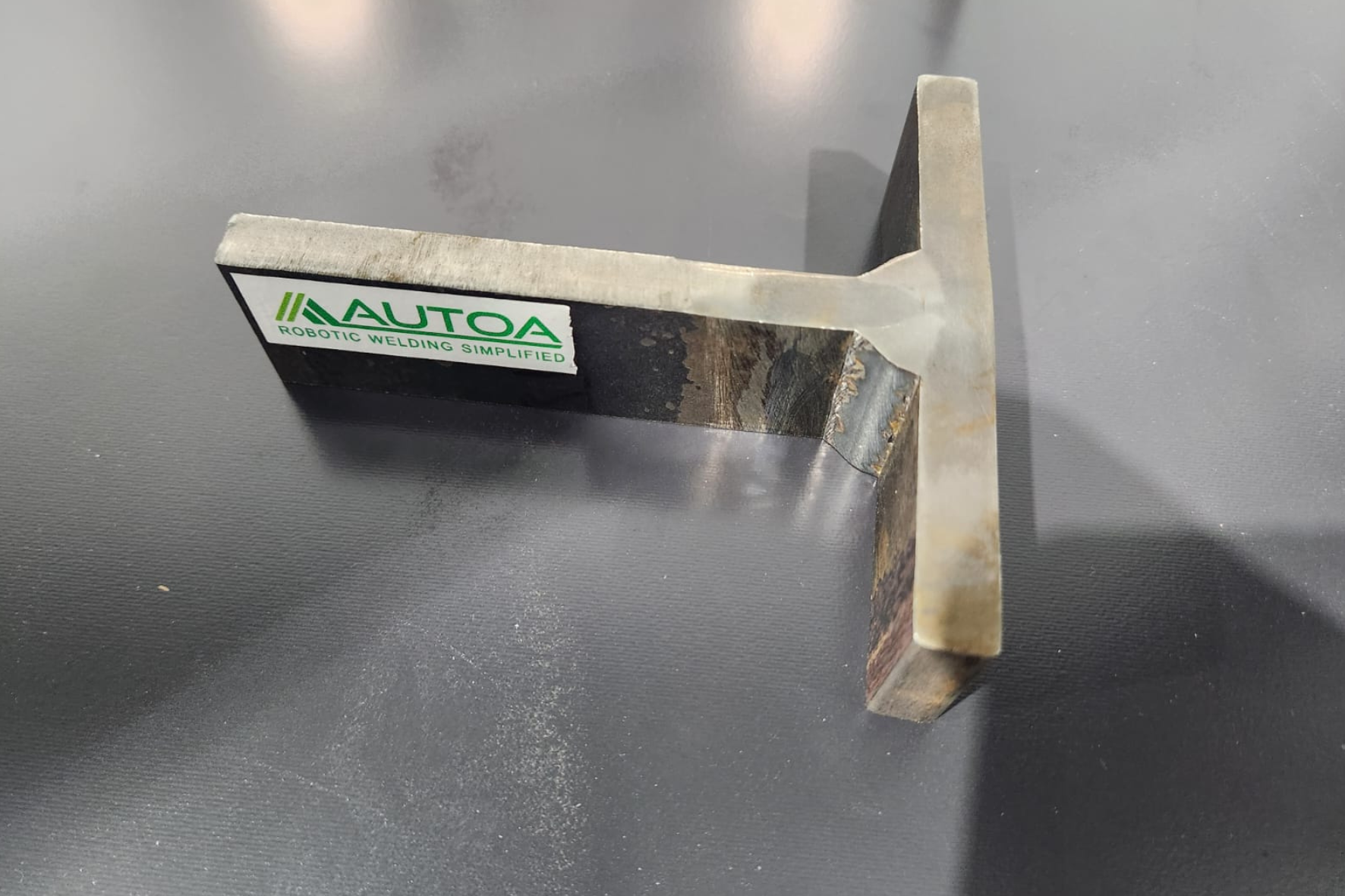

Beam with Cleats – Welding of cleats onto structural members for bolted connections.

Beam with Web Stiffeners – Welding of internal web stiffeners to improve load capacity.

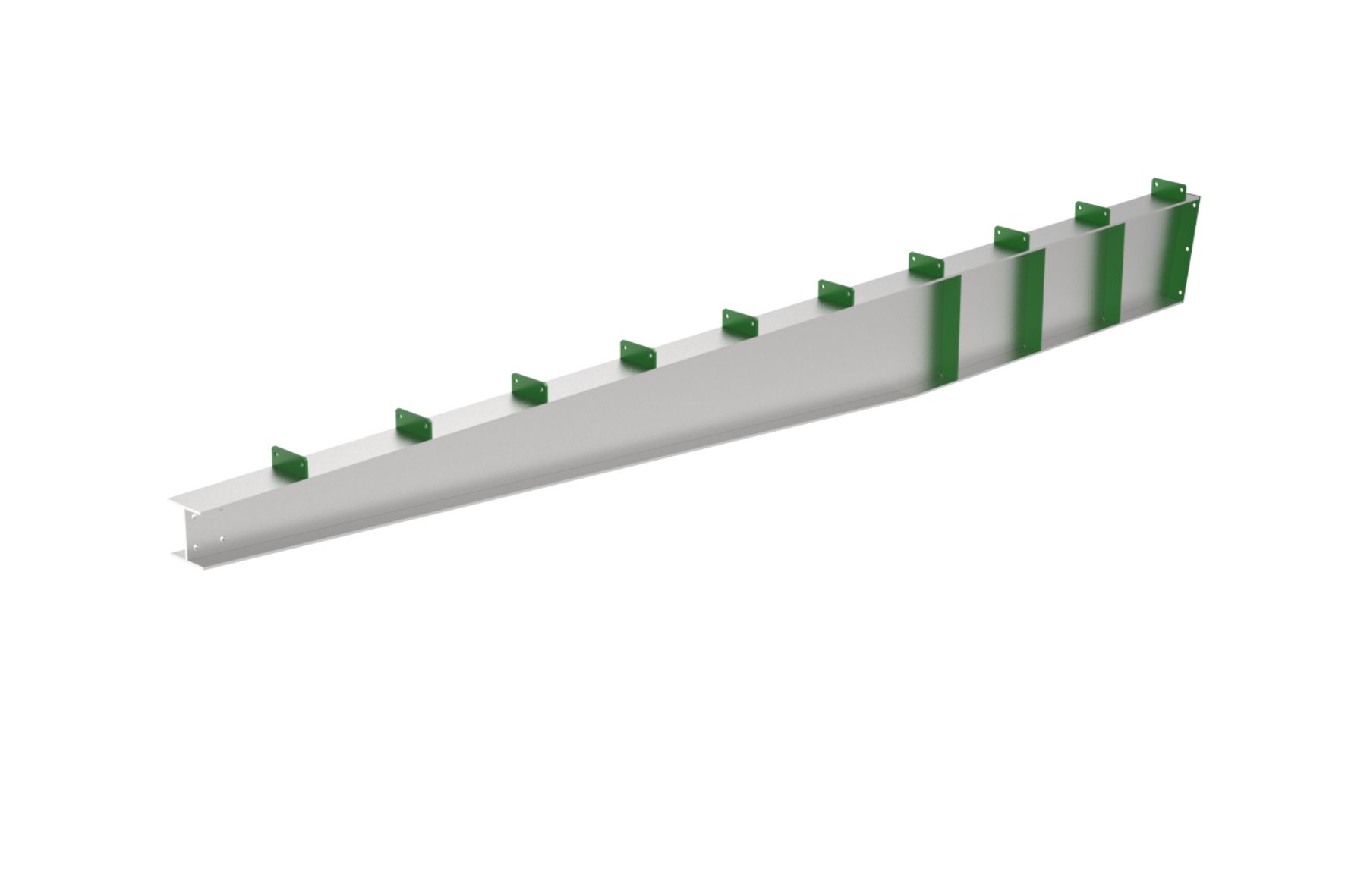

Beam with Base Plates – Welding of base plates onto beams or columns for site installation.

Autoa-SteelWeld TEchnical Data

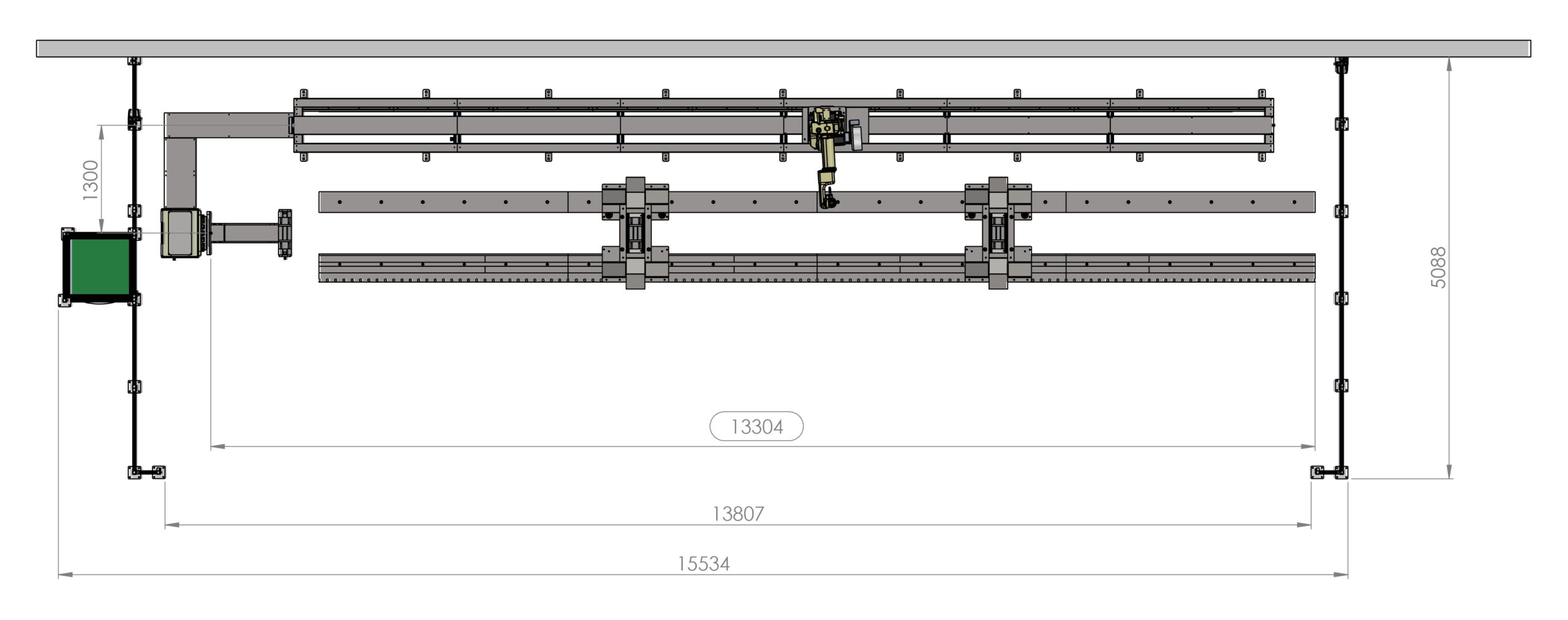

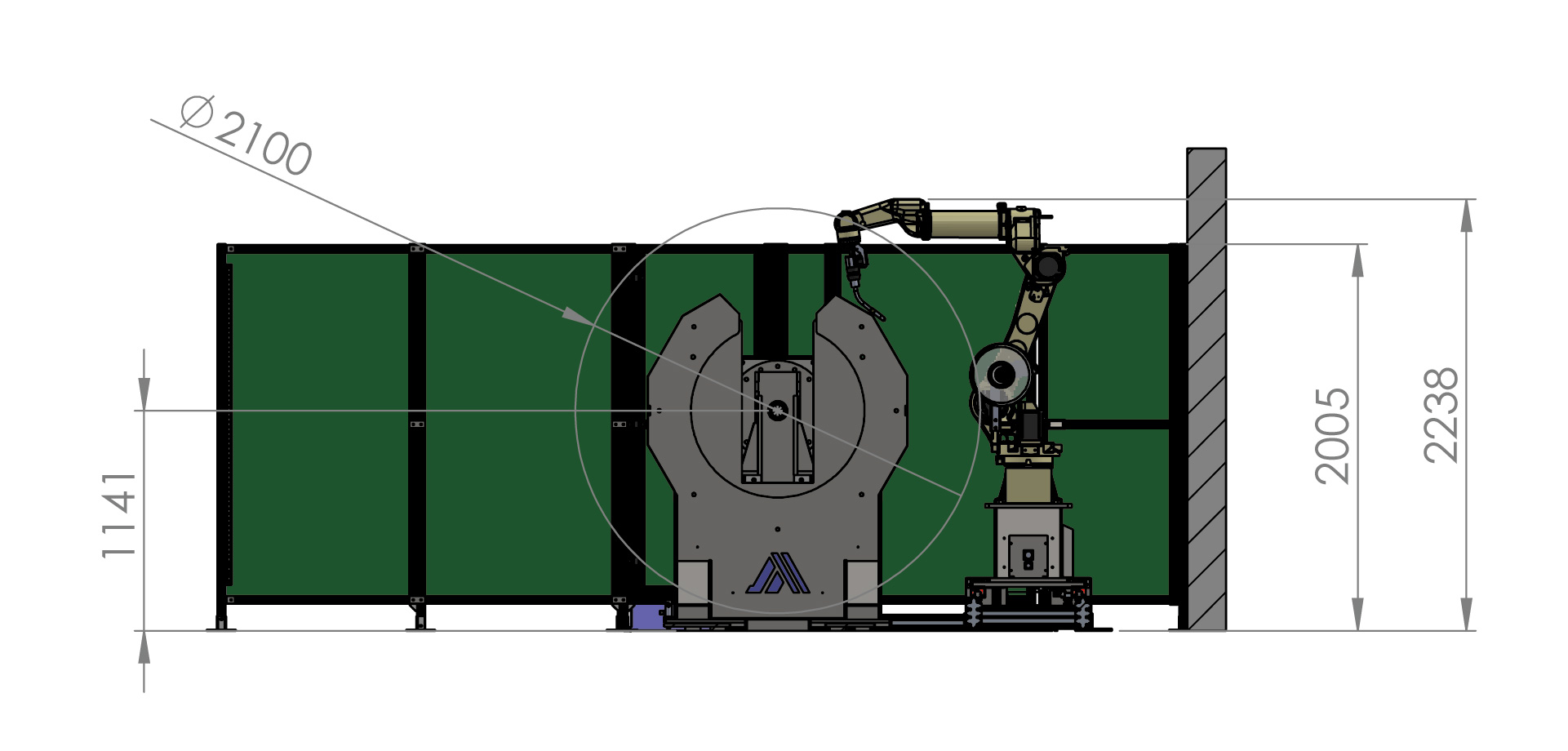

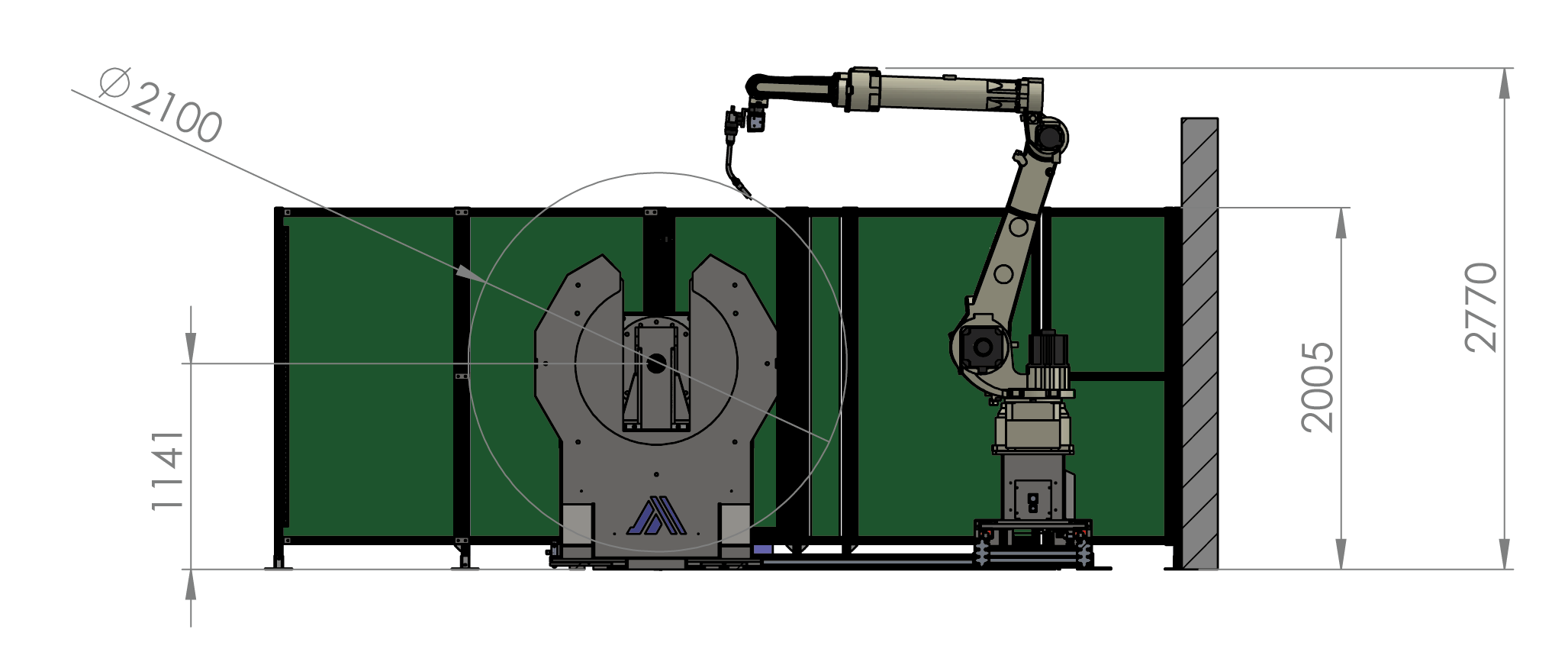

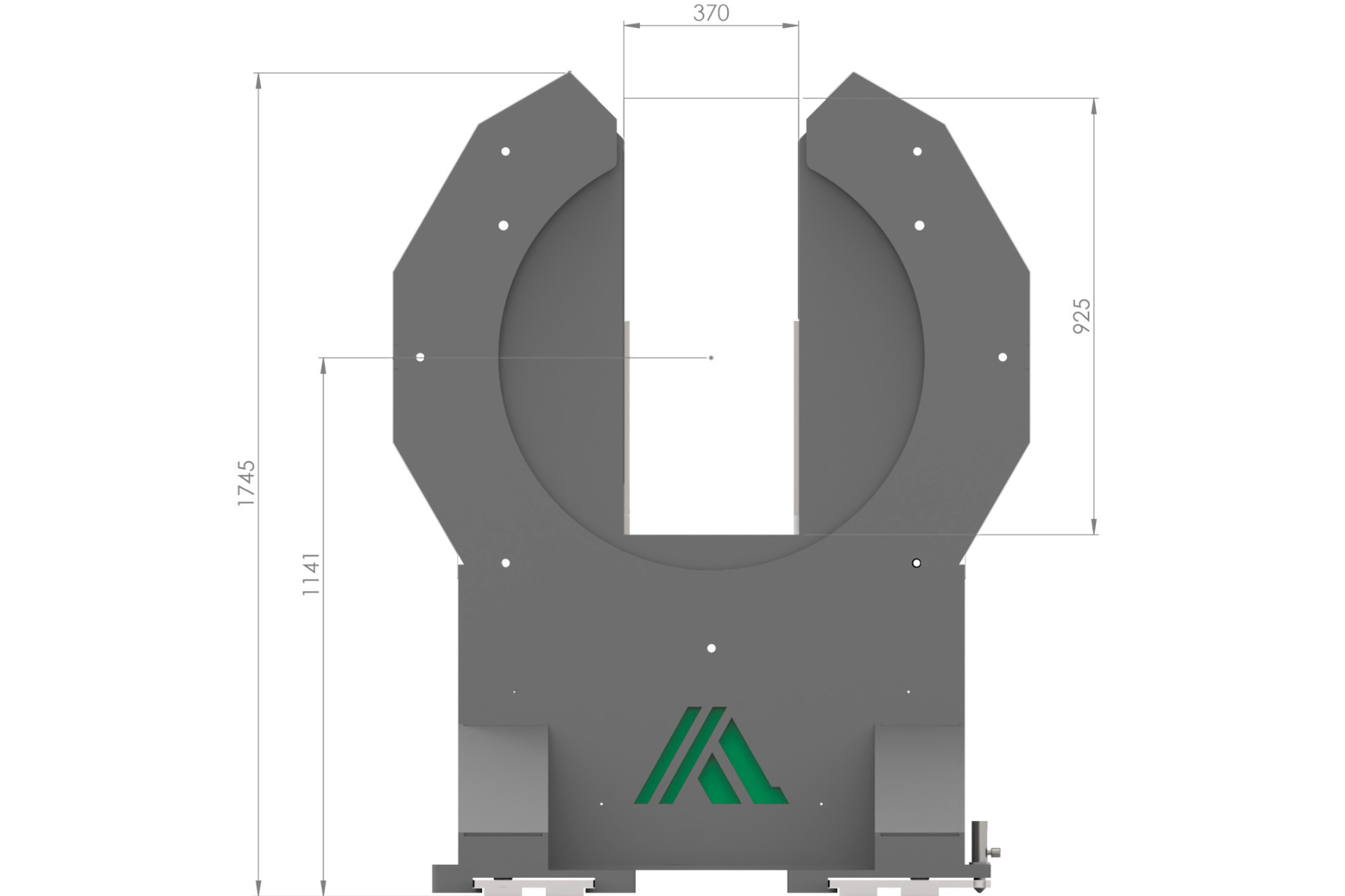

Rotator Specifications.

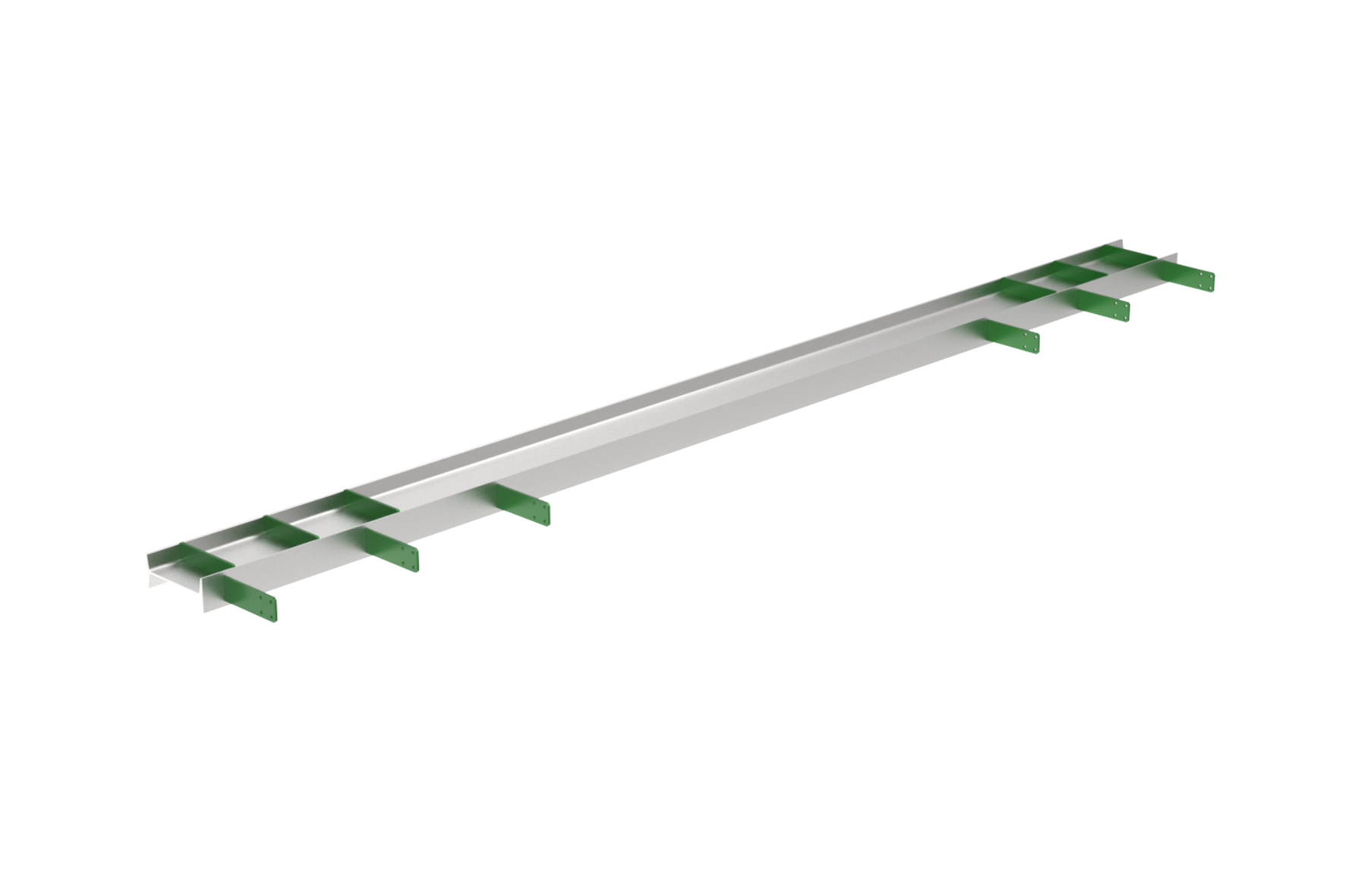

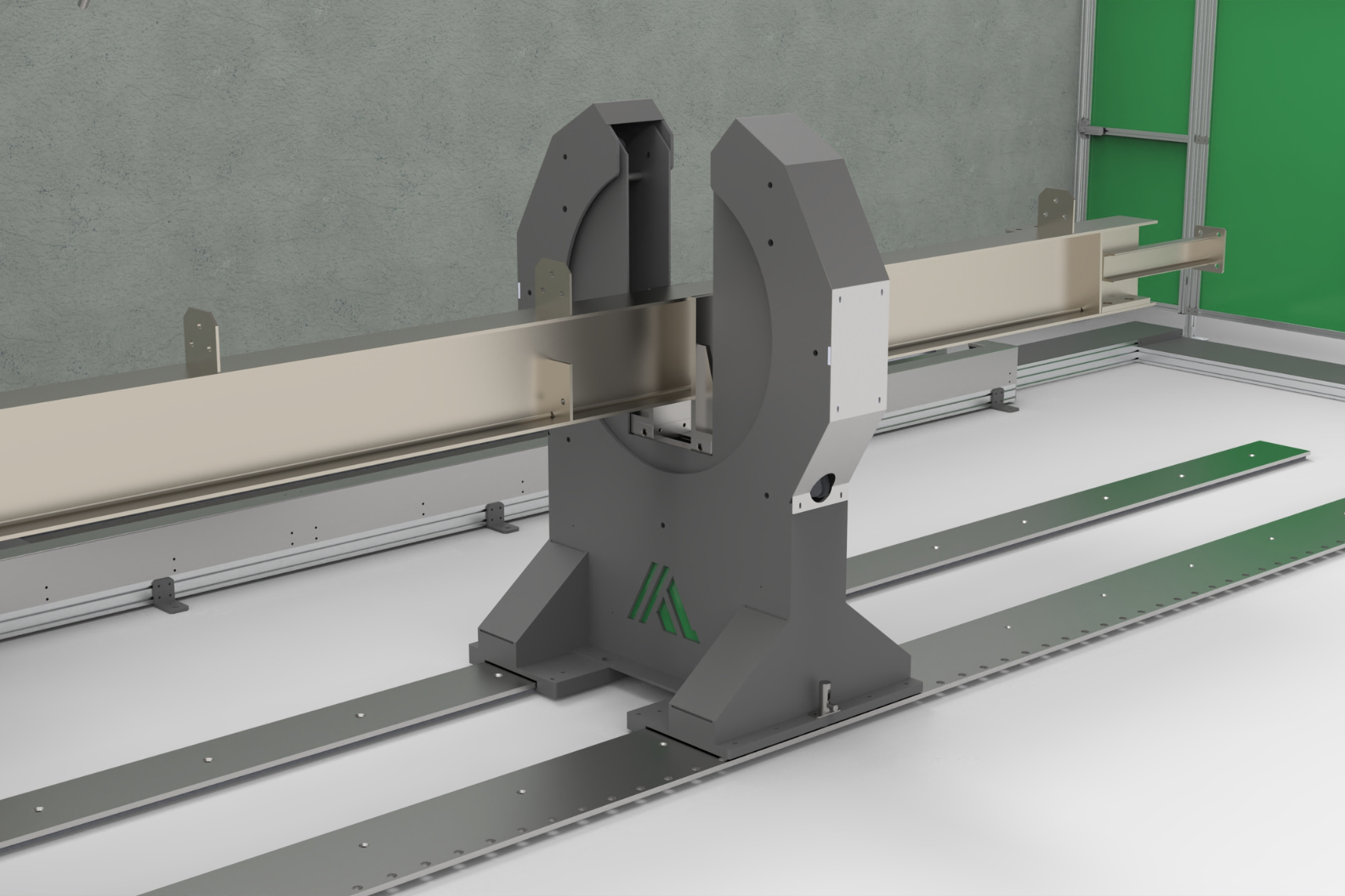

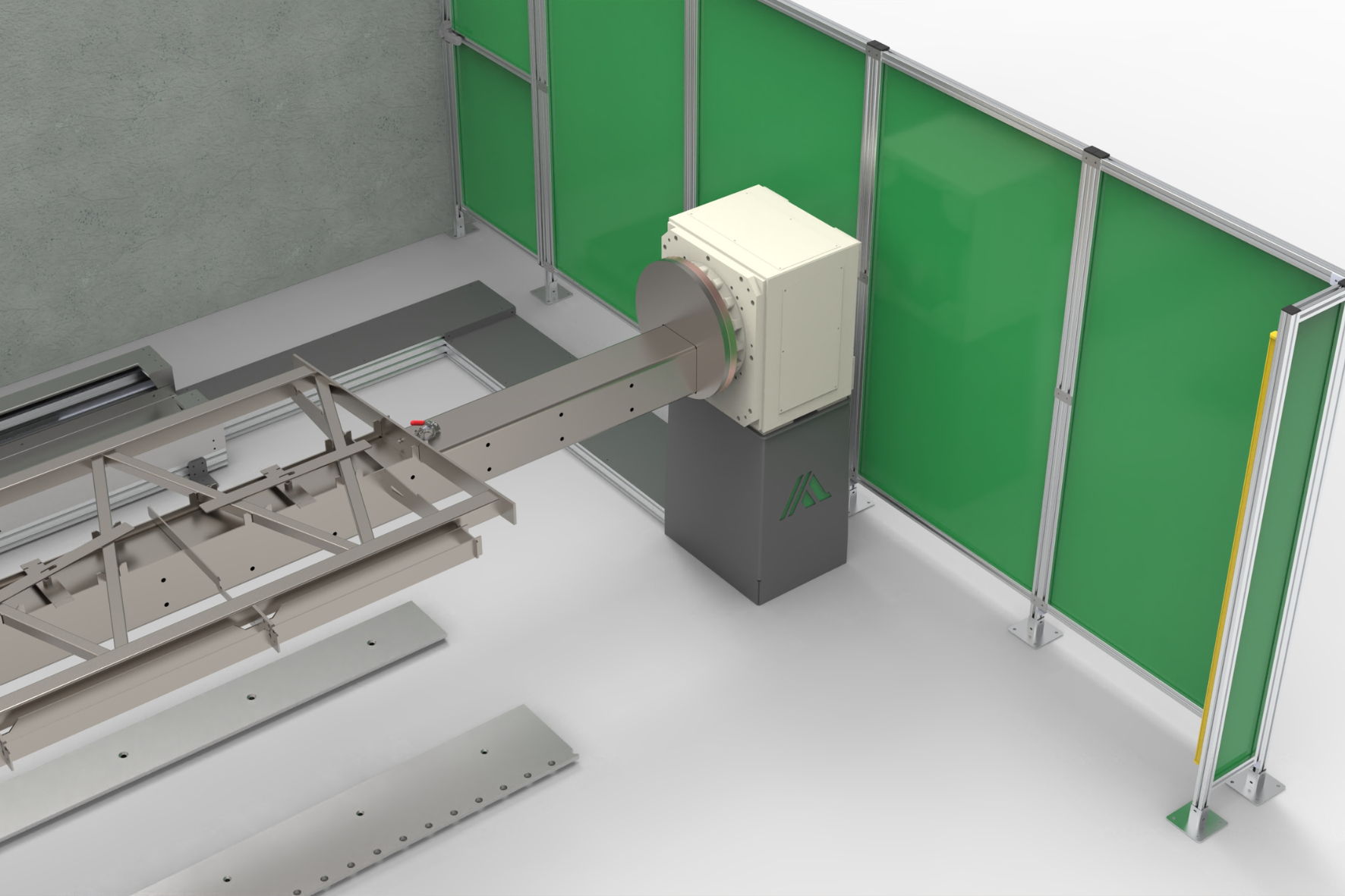

Autoa-SteelWeld includes a powered rotator system built to securely position structural steel components for optimal welding access. Capable of handling long beams, trusses and large welded assemblies, the rotator delivers precise, controlled movement to maintain weld access and consistency across every face.

- Payload Capacity: Up to 3000kg per side.

- Rotation Range: 360° rotation for full weld access.

- Tilting Motion: Optional tilt axis available for angled positioning.

- Clamping Options: Customisable jaws and support fixtures to suit different part profiles.

- Control Integration: Fully controlled through AutoaWeld software interface.

- Safety Features: Built-in limits and slow-start control for operator safety.

Robot Welding Specifications.

- Supported Weld Types: Fillet, butt, multi-pass, plug and slot welds.

- Material Thickness: 4mm to 50mm (depending on joint type & preparation).

- Beam Size Range: 60mm to 600mm (H), 500mm to 15m (L) — custom lengths available.

- Travel Speed: Typical weld speeds: 5mm weld – 10mm/sec, 6mm weld – 8mm/sec, 8mm weld – 6mm/sec.

- Welding Positions: Flat (PA), horizontal (PB), vertical (PC), and overhead (PE) — supported by rotator positioning.

- Joint Detection: Autoa Laser Quick Detect.

- Process & Transfer Mode: MCAW or GMAW – Spray and Pulse Transfer (PA–PB).

- Wire Type: 0.9–1.6mm solid or metal-cored wire (typically ER70S-6 or equivalent).

- Shielding Gas: Compatible with MIG/MAG shielding gases including Supashield 10, BOC 065, Coregas 10 (Ar/CO₂ mix).

- Torch Control: Automated arc start/stop, travel height control, and weave control (if applicable).

- Electrical Supply: 240V 3-phase.

- Pneumatic Requirement: 7–8 bar dry compressed air.

- Ethernet Speed: Upload/download >10 Mbps.

Why Choose Autoa-Steelweld?

Structural Steel Welding Simplified.

As labour costs rise and skilled welders become harder to find, Autoa-SteelWeld gives fabricators a simpler, more efficient way to stay productive. It streamlines repetitive welding tasks, reduces bottlenecks and helps maintain consistent quality across a growing workload.

Powered by AutoaWeld Software and servo-controlled rotators, it enables fully autonomous welding of even complex assemblies — from cleats and stiffeners to base plates. Whether you’re scaling up production or stabilising output with a smaller team, Autoa-SteelWeld is built to take pressure off your workshop and simplify structural steel welding from start to finish.

It’s a proven way to boost output, reduce overhead, and bring consistency to every weld — no matter the scale or complexity.

the process

Robot Welding Engineered For Structural Steel.

The process starts with a 3D model created in Tekla or similar software, which is then uploaded into AutoaWeld, Autoa’s robot programming software. AutoaWeld determines the optimal weld paths and generates detailed reports on time, accuracy and efficiency.

The operator loads the pre-tacked weldment into the rotators, runs the program, and initiates the welding cycle. A built-in laser sensor verifies weldment placement before welding begins, alerting the operator if realignment is needed. Once welding is complete, the robot resets to home position, ready for the next cycle.

This fully integrated process handles both simple and complex assemblies with ease — reducing errors, maintaining quality and improving overall throughput. By automating every critical step, Autoa-SteelWeld boosts productivity, minimises downtime and delivers reliable, repeatable results across every job.

AutoaWeld Programming Software

Behind Every Perfect Weld.

AutoaWeld is the intelligent programming software that powers Autoa-SteelWeld, simplifying complex welding processes. This intuitive tool allows fabricators to easily create, modify, and execute precise weld paths. With its user-friendly interface, operators can quickly set up jobs and make real-time adjustments, reducing downtime and boosting productivity.

AutoaWeld adapts seamlessly to a variety of structural steel projects, ensuring consistent, high-quality welds every time. Designed for efficiency, it streamlines operations and delivers perfect results, weld after weld.

Contact us

Steel The Show With Robot Welding.

Let’s talk about how our robotic welding solutions can help your business. As a 100% family-owned company, we’re focused on making robotic welding simple and supporting you every step of the way.