Training and Preparation is Key to Making the most out of Welding Robots

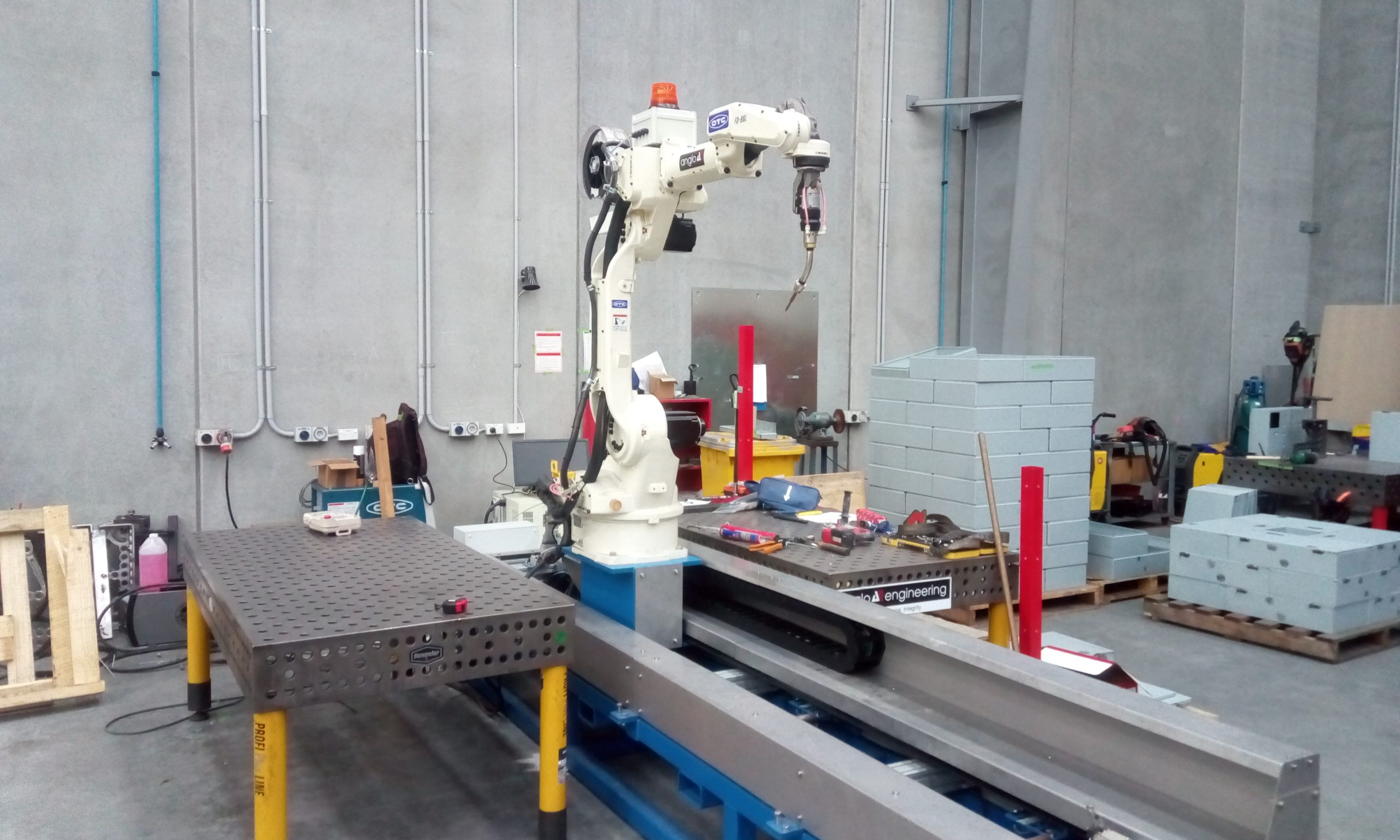

Company: anglo engineering | Cell: S-6000

EQUIPMENT

- 1x OTC Daihen FD-B6L Through-Arm, Long-Reach Arc Welding Robot with FD19 Robot Controller and Teach Pendant

- 1x OTC Daihen Welbee P500L Welding Power Source + 500A Water Cooled Torch and Water Cooler

- 2x OTC Daihen 1PC1000 Positioner Headstock

- 1x Autoa Servo Controller Robot Slider, 6000mm Travel

- 1x Autoa Tip Cleaning Station

- Safety Componentry Integrated into S-6000 Autoa Cell

TESTIMONIAL

After initially facing some challenges when learning to program Autoa’s robotic welder, Anglo Engineering in Auckland is now seeing significant benefits from their investment.

As a leading sheet metal component manufacturer, Anglo Engineering embraced Autoa robot welders in late 2018. Their decision to invest in a Autoa robotic welder was driven by a desire to streamline their welding and grinding processes.

With Autoa’s excellent support, dedication and training, Anglo Engineering has now mastered the use of robotic welders. Cy emphasizes the transformation, stating, “We’ve surpassed our initial expectations. Now, we’re consistently achieving high-quality welds, even on long seams of 1.5 meters, at impressive speeds.”

The faster welding times not only contribute to increased efficiency but also minimise heat transfer, resulting in minimal distortion of parts. This improvement has a profound impact on their production cycle, enabling Anglo Engineering to reduce cycle times and maintain consistent weld quality.

Anglo Engineering has unlocked the full potential of robotic welding technology, paving the way for continued success in their manufacturing endeavours.

Contact Us

Start Your Robotic Welding Journey Today!

Let’s talk about how our robotic welding solutions can help your business. As a 100% family-owned company, we’re focused on making robotic welding simple and supporting you every step of the way.